TM 5-3805-280-24-2

Speed Controls

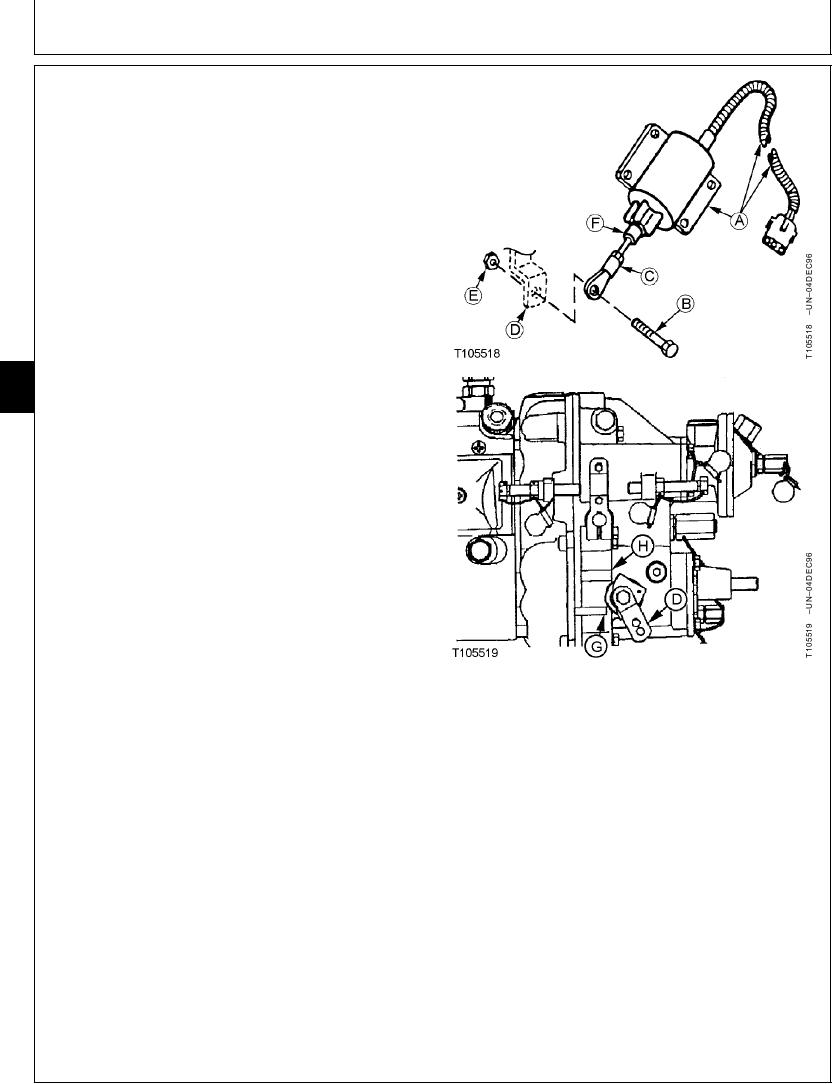

CHECK AND ADJUST FUEL SHUT-OFF

SOLENOID LINKAGE

1. Disconnect ball joint (C) from fuel shut-off lever (D).

2. Turn key switch to ON. It is not necessary to start

engine for this procedure.

3. Push plunger (F) into solenoid housing until the

plunger bottoms. With key switch ON, solenoid hold

coil is energized and will hold plunger in the run

position

4. Manually pull fuel shut-off lever (D) up against the run

position stop (upper stop) (H).

05

5. Check that hole in ball joint (C) is 3--6 mm (1/8--1/4

0515

in.) short of aligning with hole in fuel shut-off lever.

12

The 3--6 mm (1/8--1/4 in.) is the amount of overtravel

needed to compress the spring in the plunger to hold

the shut-off lever against the run position stop when

plunger is bottomed in the solenoid housing.

Ball Joint-to-Shut-Off Lever Overtravel--Specification

Distance................................................ 3--6 mm (1/8--1/4 in.) short with

key switch ON and solenoid

plunger bottomed

Adjust ball joint as necessary.

6. Manually pull fuel shut-off lever up against the run

position stop (upper stop).

A--Shut-Off Solenoid

B--Cap Screw

Adjust ball joint so hole is aligned with hole in shut-off

C--Ball Joint

lever and then turn ball joint to shorten linkage by three

D--Fuel Shut-Off Lever

turns.

E--Lock Nut

F--Plunger

G--Stop Position Stop (Lower Stop)

Hold ball joint and tighten nut.

H--Run Position Stop (Upper Stop)

Fuel Shut-Off Solenoid Plunger-to-Ball Joint Nut--Specification

Torque .............................................................................. 8 Nm (70 lb-in.)

7. Turn key switch to OFF.

Continued on next page

TX,05,UU3892

1918SEP981/2

14-23