TM 5-3805-280-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

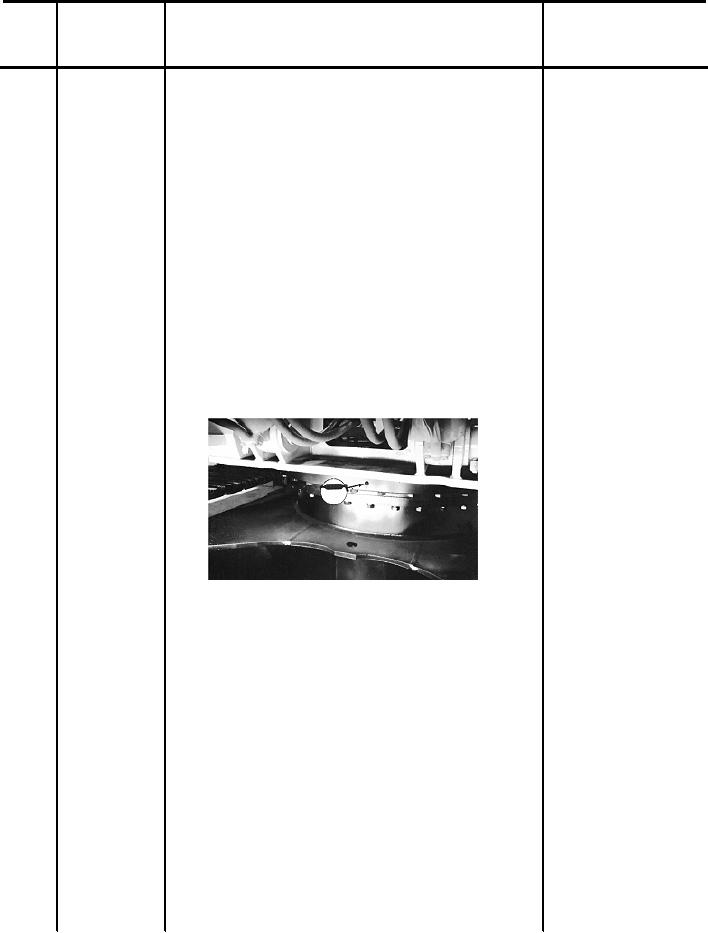

(11) Add oil until oil flows out of level check plug

hole (see Fuels and Lubricants, Chapter 1).

(12) Wrap threads of check plug and fill plug with

sealing-type tape. Install plugs. Tighten plugs

to 49 Nm (430 lb-in.).

(13) Change oil of second propel gearbox.

12

Quarterly

Grease Swing Bearing

WARNING: Prevent possible injury from

unexpected machine movement if another

person moves controls. One person must do

lubricating of swing bearing and rotating the

upperstructure. Before you lubricate swing

bearing, clear area of all personnel.

(1) Park machine on level surface.

(2) Lower bucket to the ground.

(3) Turn auto-idle switch off.

CAUTION: Turbocharger may be damaged if

engine is not properly shut down.

(4) Run engine with engine rpm dial at 1/3 position

without load for 2 minutes.

(5) Move engine rpm dial to slow idle position.

(6) Turn key switch to OFF position. Remove key

from switch.

(7) Attach a "Do Not Operate" tag on the right

control lever.

A-11