TM 5-3805-280-24-2

UNIT PREVENTIVE MAINTENANCE CHECKS AND SERVICES

FOR HYDRAULIC EXCAVATOR 230LCR/230LCRD

ITEM

INTERVAL

ITEM TO BE INSPECTED

EQUIPMENT IS NOT

NO.

PROCEDURE: DO THE PMCS AND HAVE ITEM

READY/AVAILABLE

REPAIRED, FILLED, OR ADJUSTED AS NEEDED

IF:

(8) Pull pilot control shut-off lever to locked

position.

(9) Lubricate swing bearing with 10 shots of grease

at both grease fittings.

(10) Start engine. Raise bucket several inches off the

ground and rotate the upperstructure 45

degrees.

(11) Repeat steps 2 through 9 three times.

NOTE: It is not necessary to start the engine

the last time.

13

Quarterly

Grease Swing Bearing Gear

WARNING: Prevent possible injury from

unexpected machine movement if another

person moves controls. One person must do

lubricating of swing bearing gear and rotating

the upperstructure. Before you lubricate

swing bearing gear clear area of all personnel.

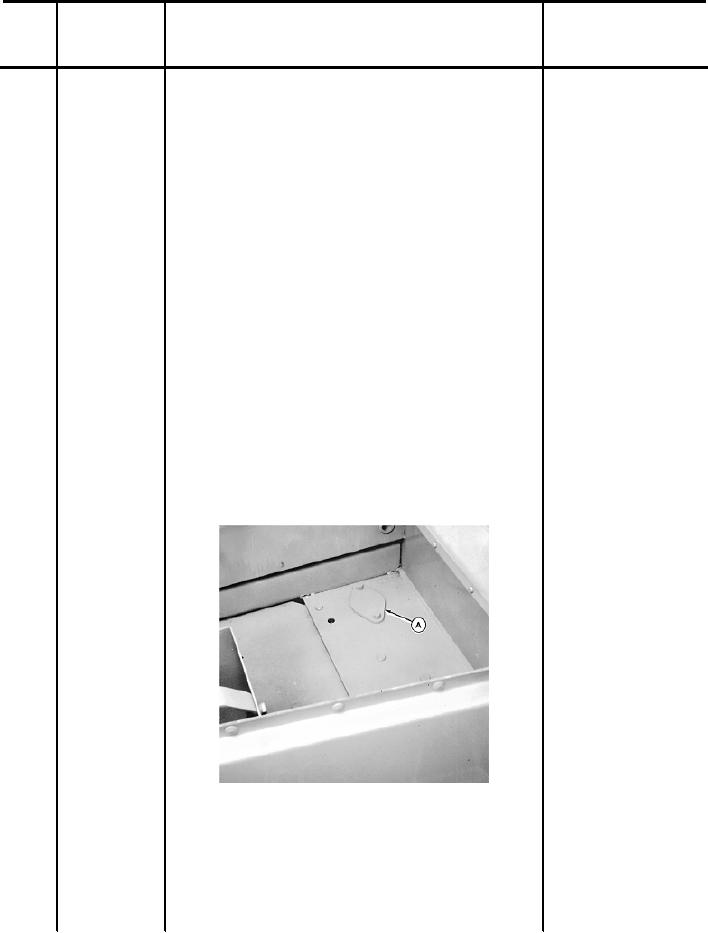

(1) Use a wrench to remove access cover (A) to

swing gear.

A-12