TM 5-3805-281-24-1

Track System

TEST TRACK ROLLER FOR OIL LEAKAGE

1. Hold shaft and turn shell several turns to seat metal

face seals.

01

2. Remove plug.

0130

7

CED,OUOE023,2265 1928JAN981/2

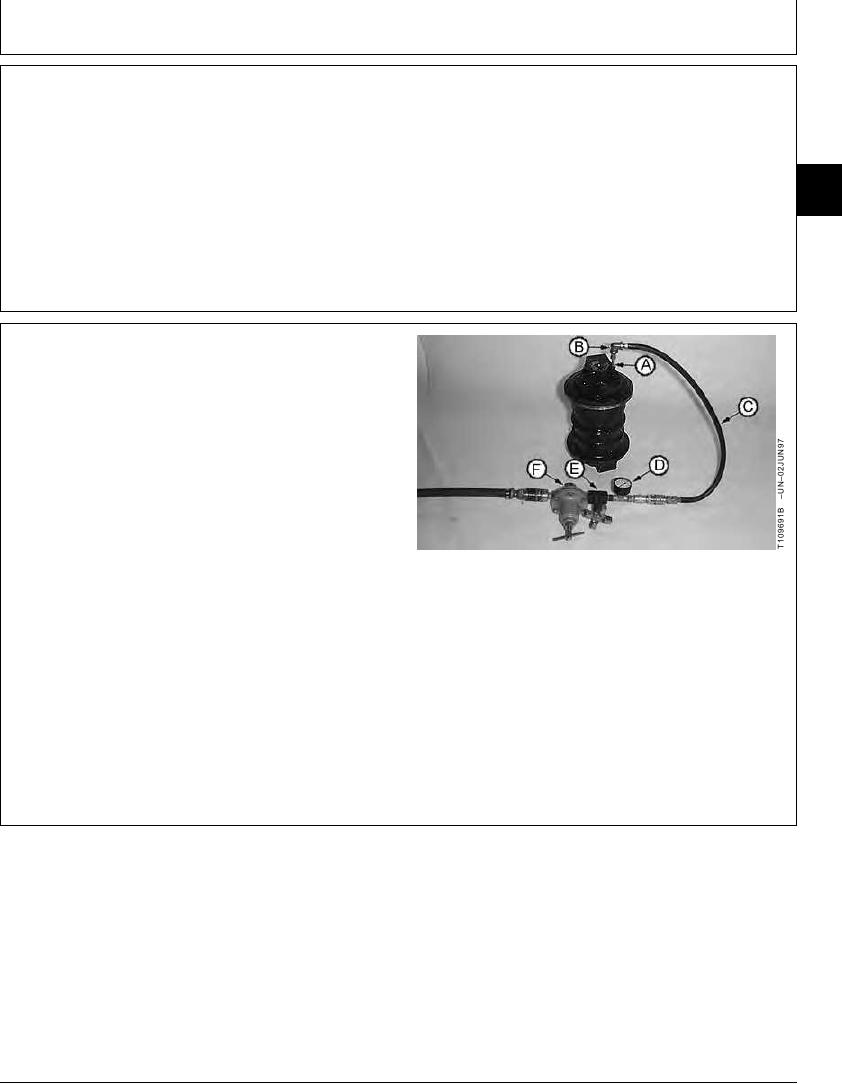

3. Install parts (A--F). Plug, barbed adapter and

connector are from a leak detector kit such at the

D05361ST Rubber Stopper/Leak Detector Kit.

4. Hold plug so it is not pushed out, slowly pressurize oil

cavity to specification using air.

Track Roller Oil Cavity--Specification

Pressure ................................................. 110 18 kPa (1.1 0.3 bar) (16

4 psi)

5. Close valve and wait for a minimum of 30 seconds.

Check for oil leakage. Check gauge to see if air

A--Plug, Barbed Adapter and Connector

pressure has decreased.

B--JT03001 Tee Fitting 7/16-20M 37 x 7/16-20F

37 SW x 7/16-20M 37

6. If there is leakage, disassemble roller and replace

C--Hose (2 used)

D--Pressure Gauge

parts as necessary.

E--Snubber (Needle) Valve

F--Air Pressure Regulator

7. Clean threads of plug using cure primer. Apply pipe

sealant to threads. Install plug.

CED,OUOE023,2265 1928JAN982/2