TM 5-3805-281-24-1

CAUTION: DO NOT heat oil over 182C (360F).

Oil fumes or oil can ignite above 193C (380F).

Use a thermometer. DO NOT allow a flame or

heating element to come in direct contact with

the oil. Heat the oil in a well-ventilated area.

Plan a safe handling procedure to avoid burns.

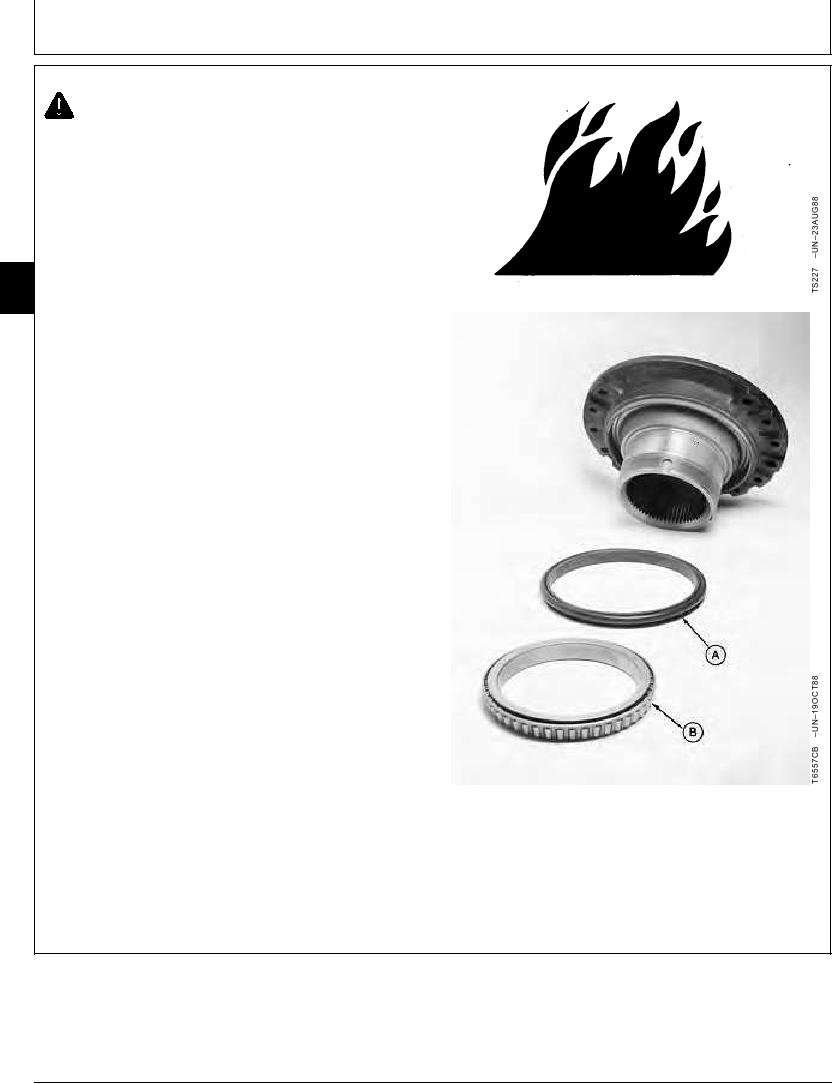

6. Heat bearing cone (B). Install cone tight against

shoulder. Cone is a press fit.

02

Bearing Cone--Specification

0250

28

Temperature ......................................................... 50--70C (122--158F)

IMPORTANT: O-ring and seat surfaces for O-ring

must be clean, dry, and oil free so

O-ring does not slip.

7. Thoroughly clean O-ring and seat surfaces in housing

and seal ring using volatile, non-petroleum base

solvent and lint-free tissues.

NOTE: A volatile, non-petroleum base solvent or talcum

powder can be used as a lubricant. Solvent must

not damage the O-ring or leave an oil residue.

8. Apply equal pressure with fingers at four equally

spaced points on seal face surface. Seal ring and

O-ring must "pop" down into place so O-ring is tight

against seal bore and seal is installed squarely.

9. Wipe finger prints and foreign material off seal face

using clean oil and lint-free tissues.

10. Apply a thin film of oil on seal face.

A--Metal Face Seal

B--Bearing Cone

Continued on next page

CED,OUOE023,159

1928MAY984/17

10-27