TM 5-3805-281-24-1

00--Propel Motor

18--Pin (3 used)

33--Spring Pin (3 used)

47--Snap Ring

02--Propel Gearbox

19--Spring Pin (3 used)

34--Second Planet Sun

48--Cap Screw (16 used)

Housing

20--Third Planet Sun Gear

Gear

49--Plug (3 used)

03--Metal Face Seal

21--Needle Bearing (6

35--Thrust Washer

51--O-Ring

05--Drum

used)

36--First Planet Carrier

52--Cap Screw (8 used)

06--Sprocket

23--Ring Gear

37--First Planet Gear (3

53--Lock Washer (8 used)

07--Lock Washer (20 used)

25--Cap Screw (28 used)

used)

55--Name Plate

08--Cap Screw (20 used)

27--Second Planet Carrier

38--Needle Bearing (3

56--Cap Screw (2 used)

09--Roller Bearing (2 used)

28--Thrust Washer (2

used)

10--Nut

used)

39--Thrust Washer (6

11--Lock Plate

29--Second Planet Sun

used)

12--Cap Screw (2 used)

Gear (3 used)

40--Pin (3 used)

14--Third Planet Carrier

30--Needle Bearing (3

41--Spring Pin (3 used)

02

15--Third Planet Gear (3

used)

42--Propel Shaft

0250

used)

31--Thrust Washer (6

44--Cover

27

17--Thrust Washer (6

used)

45--Thrust Plate

used)

32--Pin (3 used)

46--Roller Bearing

CED,OUOE023,159

1928MAY982/17

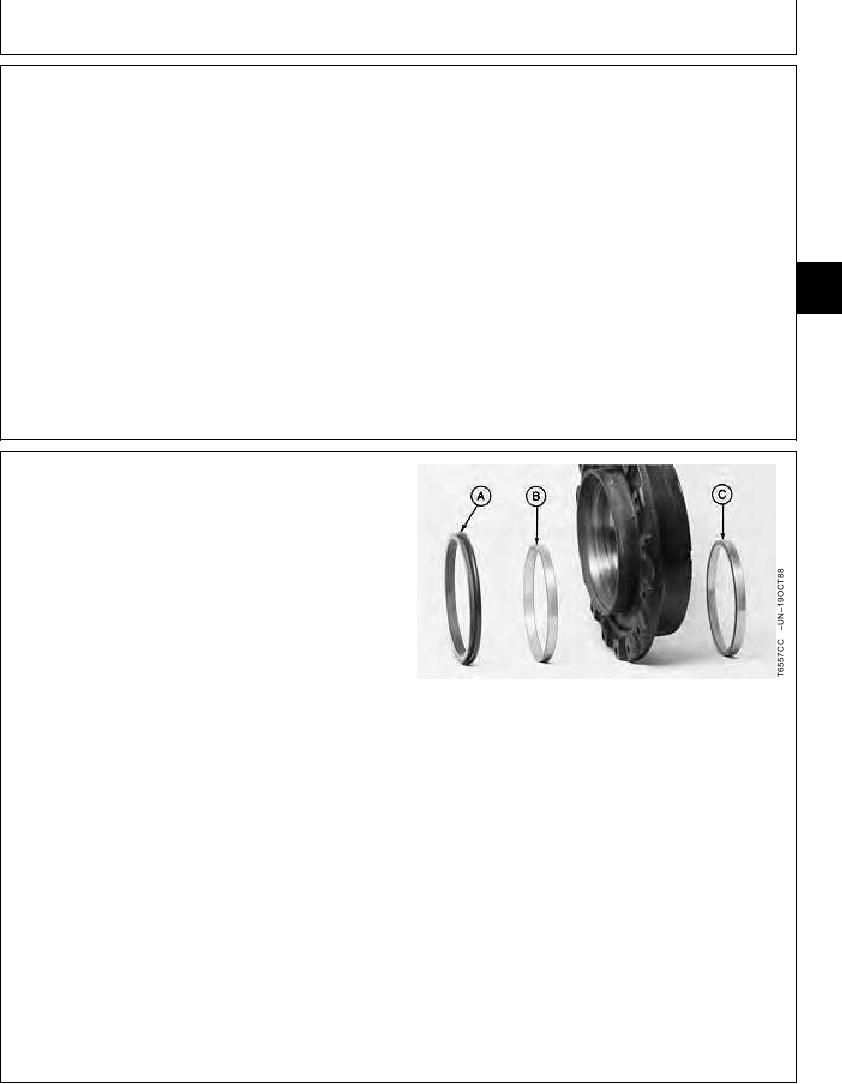

1. Install cups (B and C) tight against bottom of bore.

Cups are a press fit.

IMPORTANT: O-ring and seat surfaces for O-ring

must be clean, dry, and oil free so

O-ring does not slip.

2. Thoroughly clean O-ring and seat surfaces in housing

and seal ring using volatile, non-petroleum base

solvent and lint-free tissues.

NOTE: A volatile, non-petroleum base solvent or talcum

powder can be used as a lubricant. Solvent must

A--Metal Face Seal

not damage the O-ring or leave an oil residue.

B--Bearing Cup

C--Bearing Cup

3. Apply equal pressure with fingers at four equally

spaced points on seal face surface. Seal ring and

O-ring must "pop" down into place so O-ring is tight

against seal bore and seal is installed squarely.

4. Wipe finger prints and foreign material off seal face

using clean oil and lint-free tissues.

5. Apply a thin film of oil on seal face.

Continued on next page

CED,OUOE023,159

1928MAY983/17

10-26