TM 5-3805-281-24-1

Hydraulic System

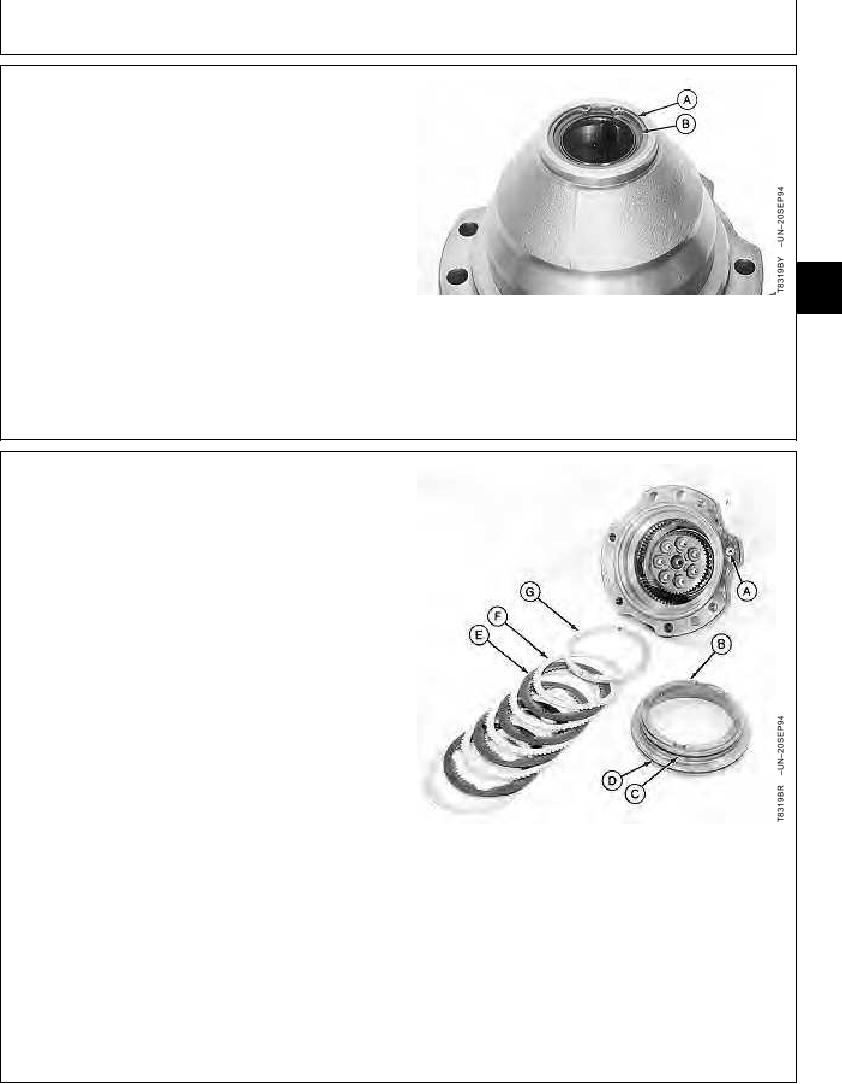

20. Apply plastic gasket (high strength) to outer diameter

of oil seal (B).

21. Install seal with spring side into bore first. Use a disk

driver to push seal to bottom of bore.

22. Apply multi-purpose grease to seal lips.

23. Install snap ring (A).

NOTE: Use a soft faced hammer to make sure bearings

02

0260

are tight against bottom of bore.

21

A--Snap Ring

24. Install motor drive shaft assembly into housing, using

B--Oil Seal

care not to damage seal lips.

CED,OUOE023,174 1901JUN989/14

25. Install spacer (G) with notches to bottom of bore and

aligned with notches in housing.

26. Install plates (F) and disks (E):

Begin with one plate and align notches in plate with

notches in housing gear.

Install one disk.

Repeat step, alternating plates and disks. Keep

notches of disks aligned with one another.

27. Apply petroleum jelly to O-rings (C and D). Install

O-rings on piston (B) with rounded side out.

28. Make sure brake port (A) is clear to allow air to exit

as piston is installed.

NOTE: To ease installation of piston apply petroleum jelly

to outer diameter of piston.

29. Install piston (B) evenly into bore.

A--Brake Port

B--Piston

C--O-Ring

D--O-Ring

E--Disk (4 used)

F--Plate (5 used)

G--Spacer

Continued on next page

CED,OUOE023,174

1901JUN9810/14

10-60