TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

REPLACE (CRANKSHAFT) OIL PUMP DRIVE

GEAR

IMPORTANT: Protect all machined surfaces of

crankshaft from grinding debris and

weld spatter when removing old gear

and installing new gear. DO NOT use a

cutting torch to remove failed gear.

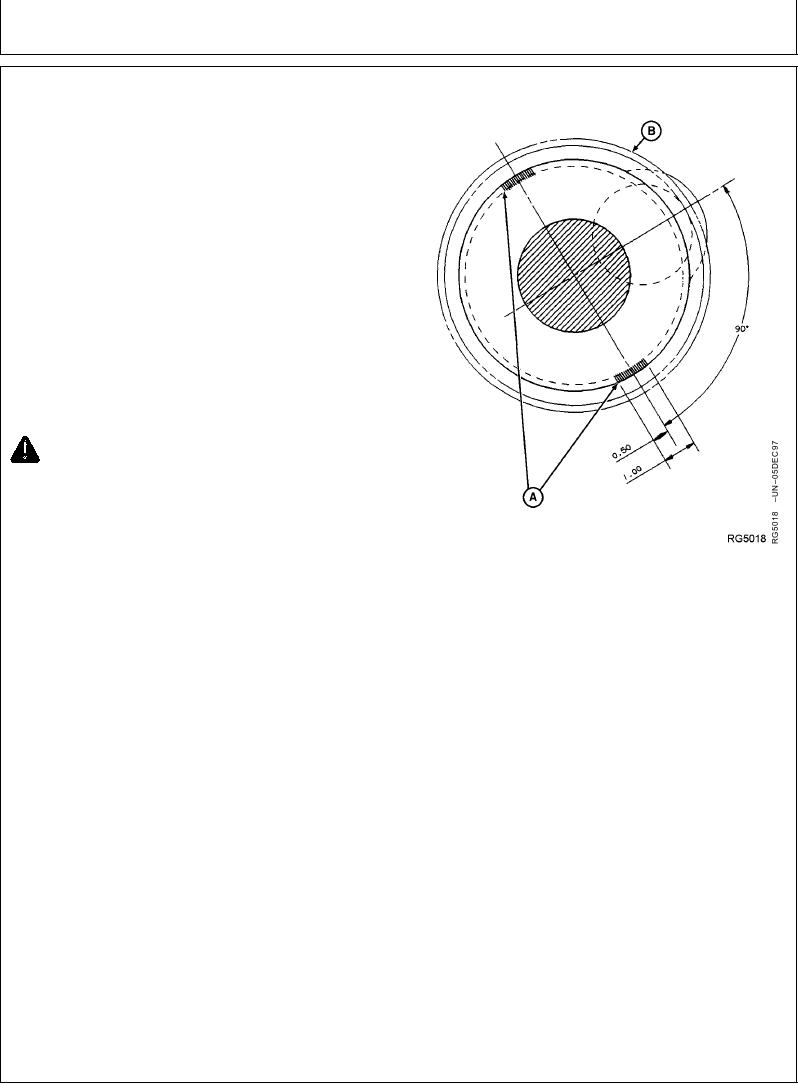

1. Using a rotary grinding wheel or parting disc, grind

weld beads (A) until flush with crankshaft flange.

2. Remove gear (B) by alternately striking gear at each

weld location using a brass drift and soft lead mallet.

3. After removal of gear, clean up O.D. of crankshaft

flange and remove any burrs or remaining weld bead

to eliminate interference when installing new gear.

CAUTION: Oil fumes or oil can ignite above

193C (380F). Use a thermometer and do not

exceed 182C (360F). Do not allow a heating

element to be in direct contact with the oil. Heat

the oil in a well-ventilated area. Plan a safe

handling procedure to avoid burns.

Removing Crankshaft Oil Pump Drive Gear

IMPORTANT: DO NOT OVERHEAT GEAR. SEE

CAUTION. Overheating may also

destroy original heat treatment of gear.

4. Heat crankshaft gear to 148C (300F) using either

heated oil or oven heat.

5. Drive gear onto crankshaft flange until flush against

shoulder.

NOTE: When driving oil pump onto crankshaft flange, the

beveled edge of gear teeth should face the

flywheel end of crankshaft.

6. Weld two 25.4 mm (1 in.) beads according to

illustration using 1/8 in. diameter 7018 welding rod.

Grind away excess weld to eliminate the possibility of

interference with cylinder block.

RG,RG34710,1177

1923OCT971/1