TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

9. Place gear on crankshaft flange. Be sure key on

crankshaft is properly aligned with keyway in gear.

IMPORTANT: When installing gear, do not gouge or

nick crankshaft flange.

10. Use JDH7 Driver to firmly seat gear against

crankshaft flange.

11. Once gear cools, reseat gear using JDH7 Driver.

RG,RG34710,1178

1923OCT972/2

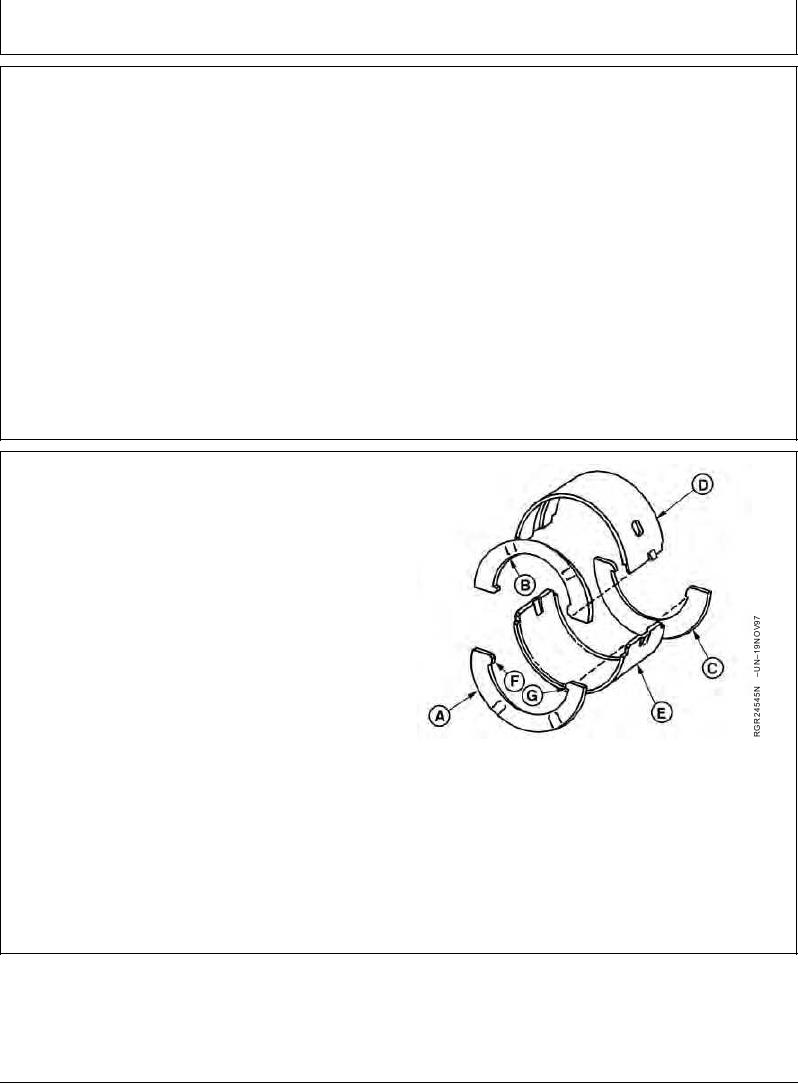

INSPECT THRUST BEARINGS

Check thrust surfaces of the thrust bearing and the thrust

bearing journal on crankshaft and replace as necessary.

Thrust bearing are available in each of the previously

mentioned insert undersizes. An oversized thrust washer

set containing one regular size washer and two 0.18 mm

(0.007 in.) oversized washers is also available.

NOTE: Thrust bearing must be installed with slots facing

crankshaft flange. Two halves (A) and (C) go on

cap side, not block.

Crankshaft Main Thrust Bearing Assembly

A--Lower Rear Thrust Washer

B--Upper Rear Thrust Washer

C--Lower Front Thrust Washer

D--Main Bearing Block Thrust Bearing

E--Main Bearing Cap Thrust Bearing

F--Large Tang

G--Small Tang

RG,RG34710,1179

1923OCT971/1