TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

IMPORTANT: Alignment and installation tools must

be clean to hold runout within

specification and to assure proper

positioning on crankshaft flange so oil

seal does not fail prematurely.

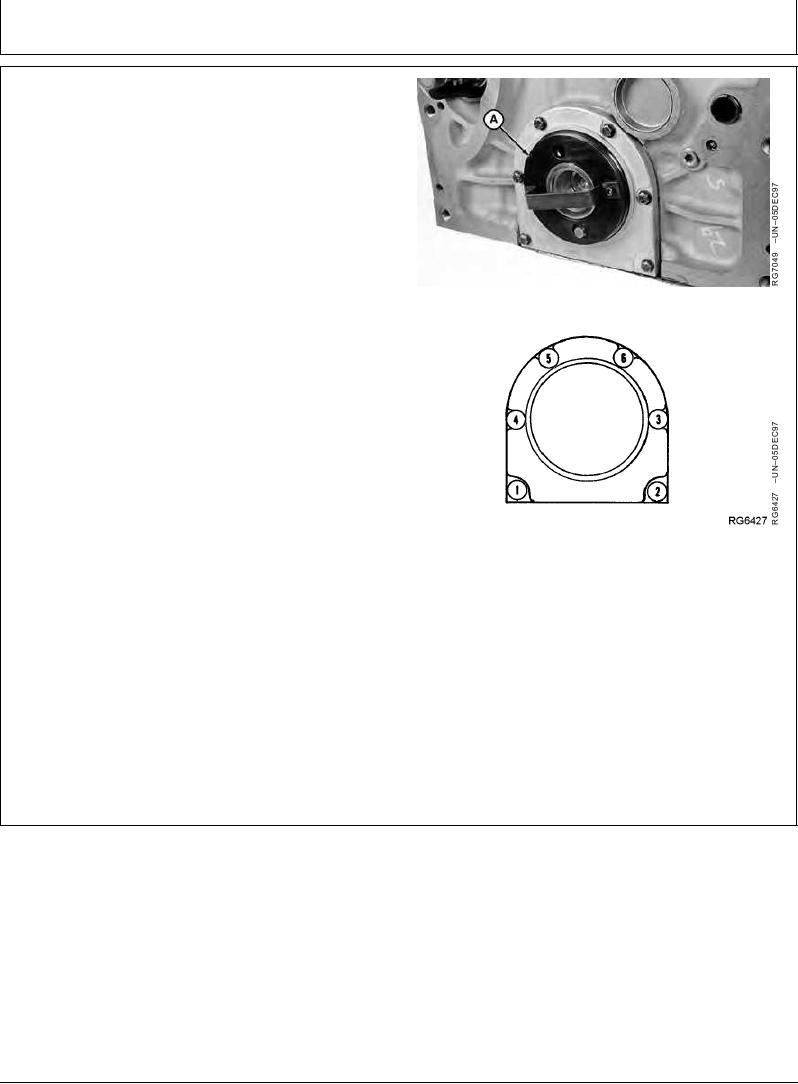

3. Slip the JDG796 Alignment Tool (A) over crankshaft

flange and into seal housing bore to center oil seal

housing.

The tool is designed to center the oil seal housing in

relation to crankshaft flange. However, measuring the

Centering Rear Oil Seal Housing

seal housing runout after installation with a magnetic

base dial indicator is recommended. Runout should not

exceed 0.15 mm (0.006 in.).

4. Position bottom of oil seal housing so it is recessed

0.000--0.050 mm (0.000--0.002 in.) inside cylinder

block-oil pan rail. Tighten seal housing cap screws to

27 Nm (20 lb-ft), using sequence shown in bottom

illustration, beginning with cap screw No. 1.

5. Remove alignment tool from end of crankshaft flange.

6. Check oil seal housing runout with a magnetic base

Cap Screw Tightening Sequence for Rear Oil Seal Housing

dial indicator. (See CHECK OIL SEAL HOUSING

RUNOUT, later in this group.)

7. Trim off excess gasket material extending below

bottom of oil seal housing.

RG,RG34710,1182

1923OCT972/2

11-242