TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

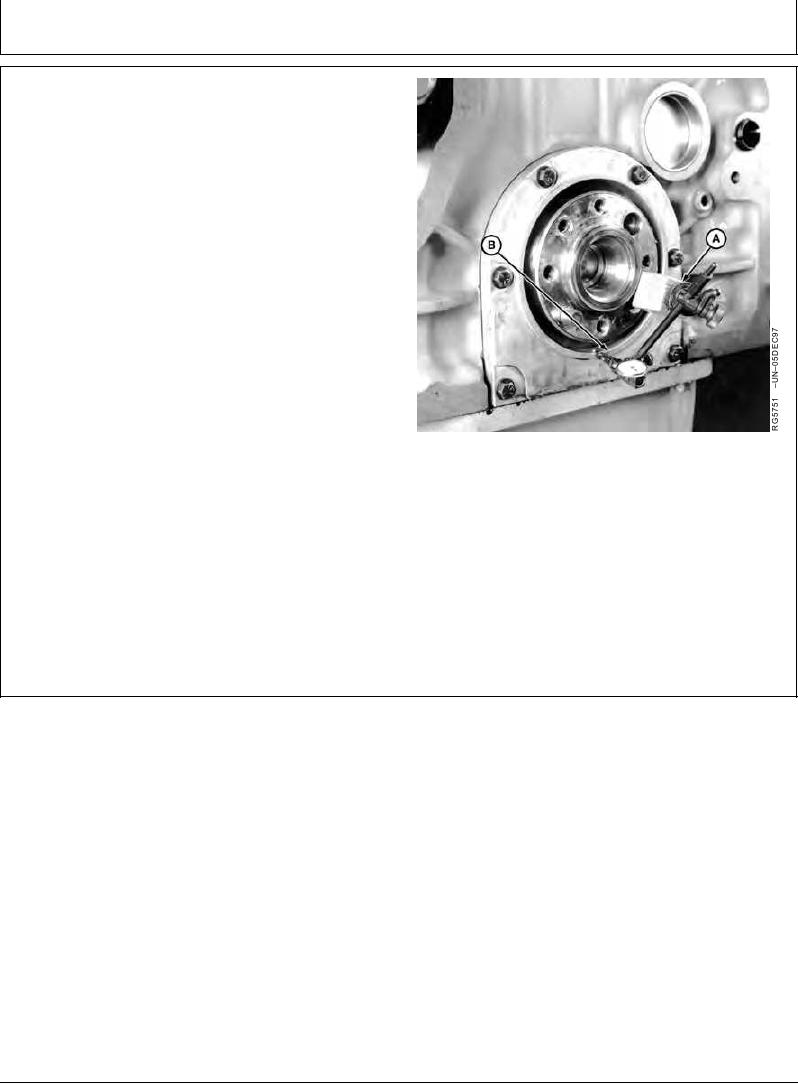

CHECK OIL SEAL HOUSING RUNOUT

IMPORTANT: On service "short block" assemblies,

rear oil seal housing runout is preset at

the factory. Do not remove housing

from block.

1. Position magnetic base dial indicator (A) on end of

crankshaft flange as shown. Preset dial indicator tip on

I.D. of oil seal housing bore (B).

2. Zero dial indicator and rotate crankshaft one full

revolution, observe full indicator movement. The

maximum oil seal housing bore runout is 0.15 mm

(0.006 in.).

If runout exceeds specification, loosen cap screws and

adjust housing to obtain an acceptable runout while

keeping bottom of seal housing flush with oil pan

mating surface.

Checking Rear Oil Housing Runout

3. Recheck oil seal housing bore runout. If runout still

exceeds specification, oil seal housing bore is possibly

distorted and should be replaced. See INSTALL

CRANKSHAFT REAR OIL SEAL HOUSING, earlier in

this group.

RG,RG34710,1183

1923OCT971/1