TM 5-3805-281-24-2

Crankshaft, Main Bearings, and Flywheel

CRANKSHAFT REAR OIL SEAL AND WEAR

SLEEVE HANDLING PRECAUTIONS

Use the following precautions for handling seal and wear

sleeve:

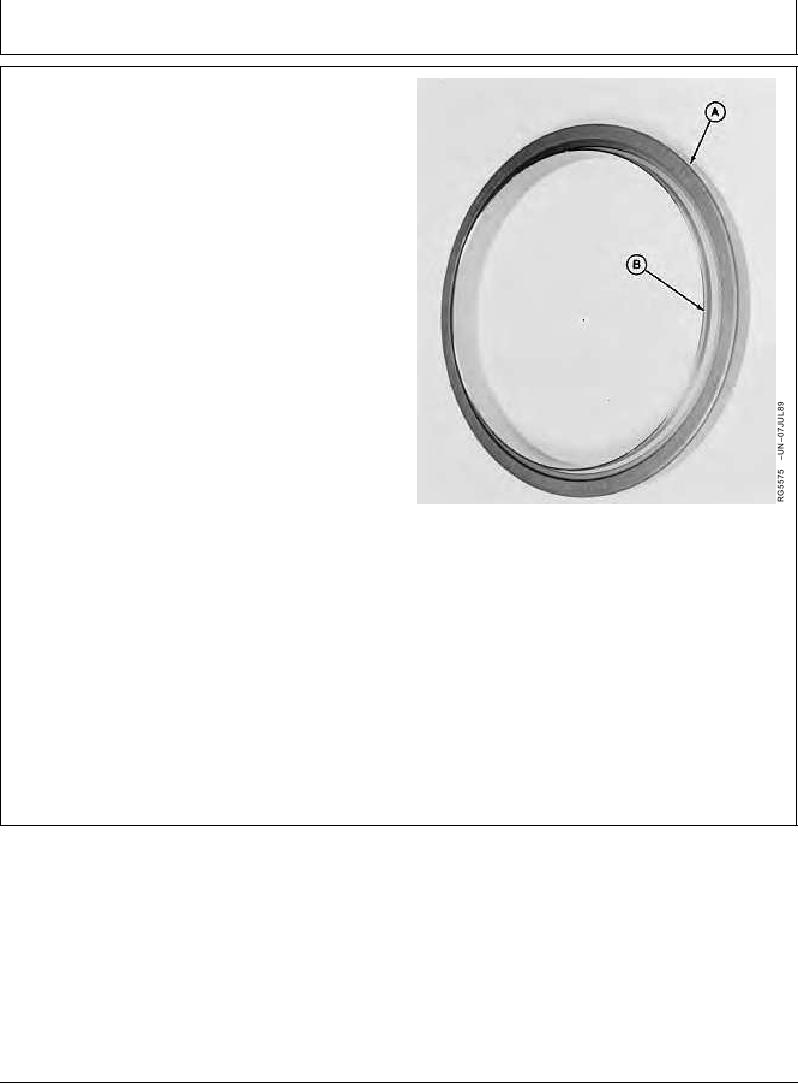

Seal (A) and wear sleeve (B) are assembled. DO NOT

SEPARATE. If parts become separated, discard and

replace with a new assembly. Attempts to reassemble will

cause the wear sleeve to damage the seal allowing

engine oil to leak past seal.

Always install seal and wear sleeve assembly immediately

after removal from plastic bag to avoid possible dirt

No lubrication of any kind is to contact seal when

installing. Use of a lubricant may result in premature seal

failure.

Install oil seal/wear sleeve assembly with the open side of

seal and wear sleeve I.D. chamfer toward the engine. If

seal is reversed, engine oil may be lost because grooves

in oil seal lip would be incorrect with respect to direction

Crankshaft Rear Oil Seal and Wear Sleeve

of crankshaft rotation.

Oil seal/wear sleeve assembly MUST be installed with the

JDG476(85) Crankshaft Rear Oil Seal Installation Tool

Set. Tool set consists of JDG477 (85) Pilot and JDG478

Driver.

RG,RG34710,1184

1923OCT971/1