TM 5-3805-281-24-2

Fuel System

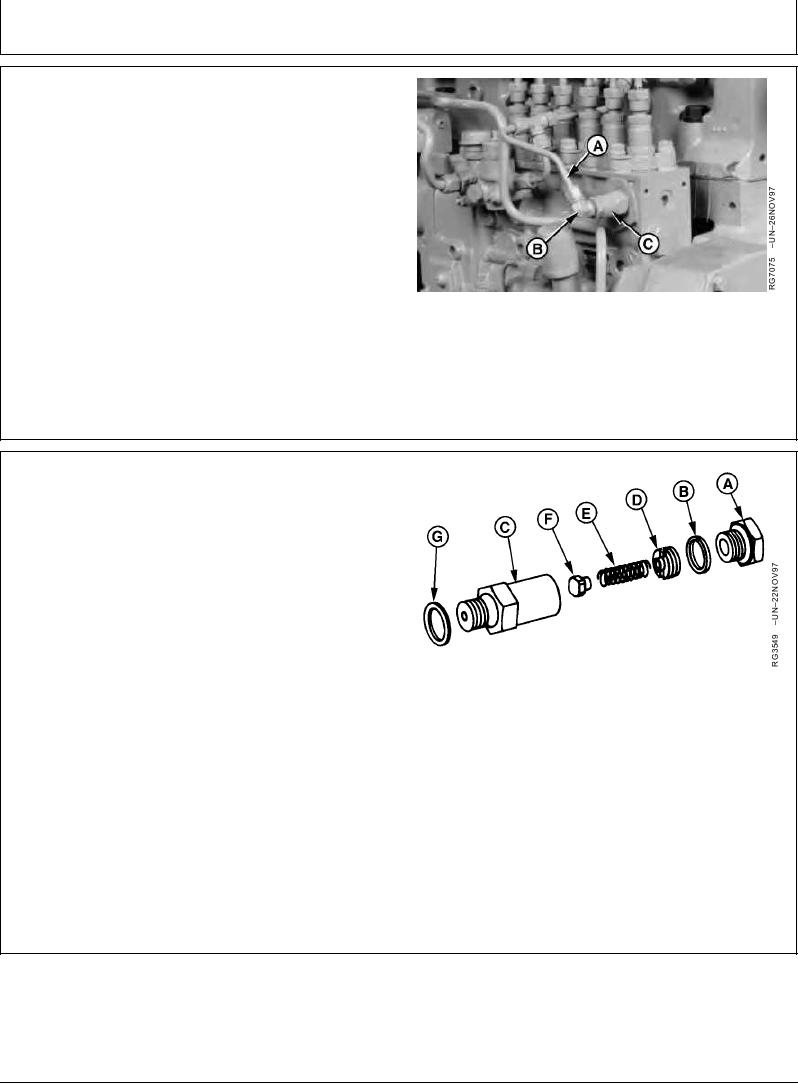

SERVICE INJECTION PUMP OVERFLOW

VALVE

NOTE: Overflow valve can be serviced with injection

pump installed.

1. Remove leak-off line (A) from elbow (B). Remove

elbow from overflow valve assembly (C).

2. Remove valve assembly from pump.

Removing Injection Pump Overflow Valve

RG,RG34710,1295

1923OCT971/2

3. Remove reducer (A) and copper washer (B) from valve

body (C). Discard copper washer.

4. Unscrew for spring seat (D); then remove spring (E)

and valve (F).

5. Inspect for foreign material imbedded in seat of nylon

valve.

6. Check spring to see that it is not weak or broken.

7. Wash all parts in solvent and air dry.

Inspecting Injection Pump Overflow Valve

A--Reducer

NOTE: There is no adjustment on valve to regulate

B--Washer

housing pressure. If suspected that valve is

C--Valve Body

malfunctioning, replace valve to restore proper

D--Spring Seat

operation.

E--Spring

F--Valve

G--Washer

8. Reverse order of removal for reassembly of overflow

valve. Install new copper washers.

RG,RG34710,1295

1923OCT972/2