TM 5-3805-281-24-2

Buckets

7. Preheat shank and cutting edge. Check temperature

using a temperature stick to be sure correct

33

temperature is obtained.

3302

8

Tooth Shank--Specification

Preheat Temperature ....................................... 204--316C (400--600F)

IMPORTANT: All weld beads must be continuous

starting at rear center, around the

corner and along the side for a good

strong weld joint. DO NOT start or stop

welding at a corner.

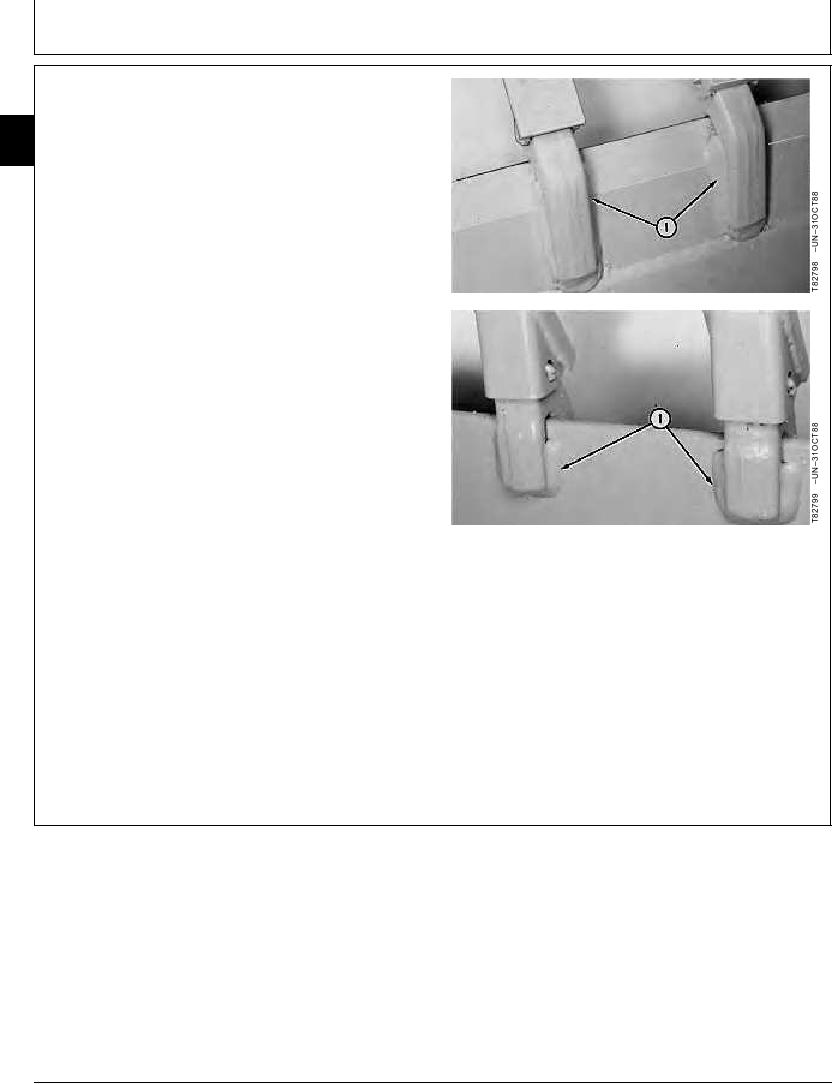

8. Weld shank to cutting edge using 12.7 mm (0.5 in.)

fillet weld (1).

Tooth Shank--Specification

Fillet Weld....................................................................... 12.7 mm (0.5 in.)

Starting at rear center of shank, weld a continuous bead

across end, around corner, and along side, stopping from

edge of cutting edge as specified.

Tooth Shank--Specification

Distance................................................. 25 6 mm (0.98 0.24 in.) from

1--Fillet Weld

weld edge

Alternating from side to side, make as many passes as

necessary to get the specified bead size.

9. Allow weld area to cool slowly at room temperature.

TX,33,GG2396 1913DEC964/4

19-8