TM 5-3805-281-24-2

Hydraulic System

1--Cap Screw (6 used)

10--Cover

19--Lock Washer (4 used)

26--Snap Ring

2--O-Ring

11--O-Ring

20--Cap Screw (4 used)

27--Cap Screw

3--Plug

12--Nut (3 used)

21--Plug

28--Bracket

33

4--Filter

13--Rod

22--Cap Screw and Lock

29--Level Switch

3360

5--O-Ring

14--Suction Strainer

Washer (6 used)

30--Filter

131

6--Allen Screw (4 used)

15--Washer Seal

23--Suction Pipe

31--Valve

7--Housing

16--Cap Screw (2 used)

24--O-Ring

32--Spring

8--Packing

17--Gauge

25--Oil Cooler Bypass

33--O-Ring

9--Cap Screw (6 used)

18--Washer (4 used)

Valve

34--Cover

Rod and Suction Strainer--Specification

NOTE: It is not necessary to drain and remove the

hydraulic oil tank if only the return filter

Length .................................................. 702 mm (27.6 in.) from end of

element (30) is being removed. (See

rod to bottom of suction strainer

procedures in this group.)

Distance ................................................. 20 mm (0.79 in.) from end of

rod to top nut

1. Tighten cap screws (1, 9 and 22).

Tighten nut (12).

Cover-to-Oil Tank Cap Screw--Specification

Rod-to-Suction Strainer Nut--Specification

Torque....................................................................... 49 Nm (36 lb-ft)

Torque.................................................................... 17 Nm (153 lb-in.)

2. Adjust rod (13) so length from end of rod to bottom

of filter (screen) (14) is to specification. Tighten nuts

(12) at top end of rod so top nut is the specified

distance from end of rod.

CED,OUOE026,8

1918JUN982/2

REMOVE AND INSTALL RETURN FILTER

AND BYPASS VALVE

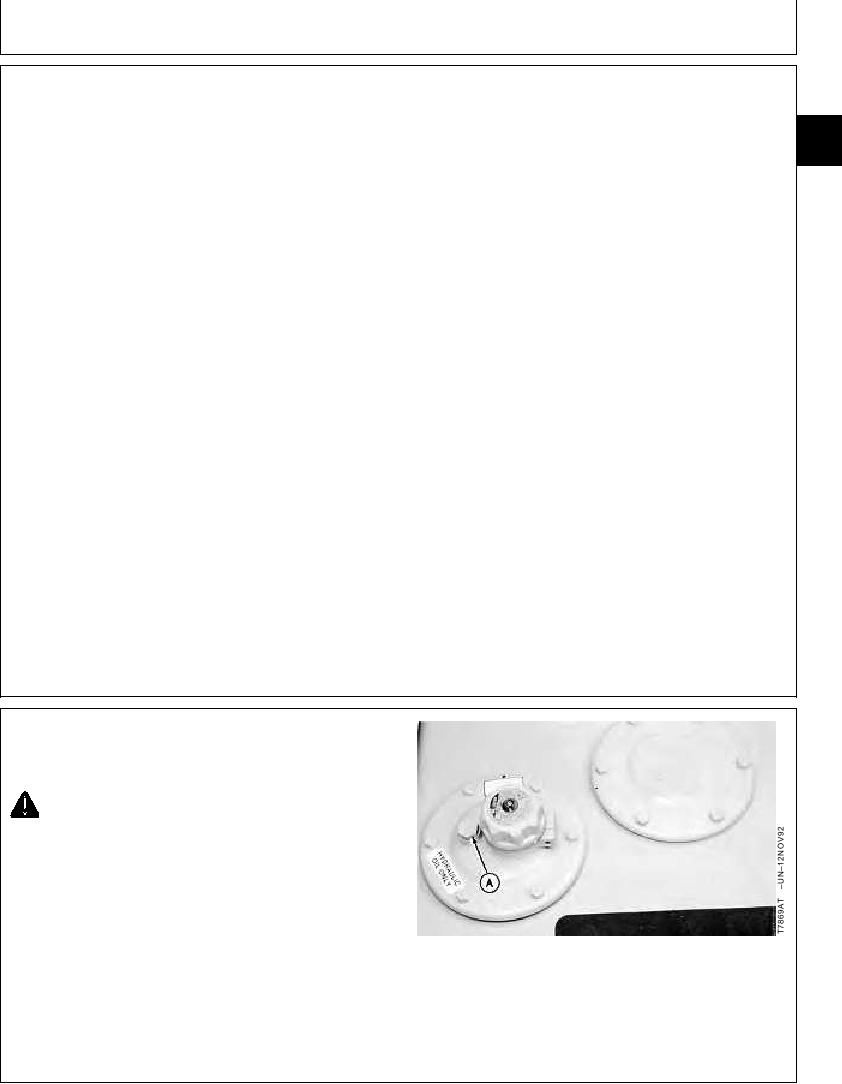

CAUTION: The hydraulic oil tank is pressurized.

High pressure release of oil from pressurized

system can cause serious burns or penetrating

injury. Release pressure from tank by loosening

vent plug. It is not necessary to remove vent

plug.

1. Loosen vent plug (A) to release air pressure from

hydraulic oil tank.

A--Vent Plug

Continued on next page

CED,OUOE026,7

1918JUN981/3