TM 5-3805-294-23-1

FIELD MAINTENANCE

BENT TRACK SHOES

INITIAL SETUP:

Equipment Condition

Tools and Special Tools

Machine safely parked and shut down

Tool Kit, General Mechanic's: Automotive

(TM 5-3805-294-10). (Volume 5, WP 0794)

(Volume 5, WP 0796, Table 2, Item 119)

References

TM 5-3805-294-10 (Volume 5, WP 0794)

Volume 3, WP 0391

TROUBLESHOOTING PROCEDURE

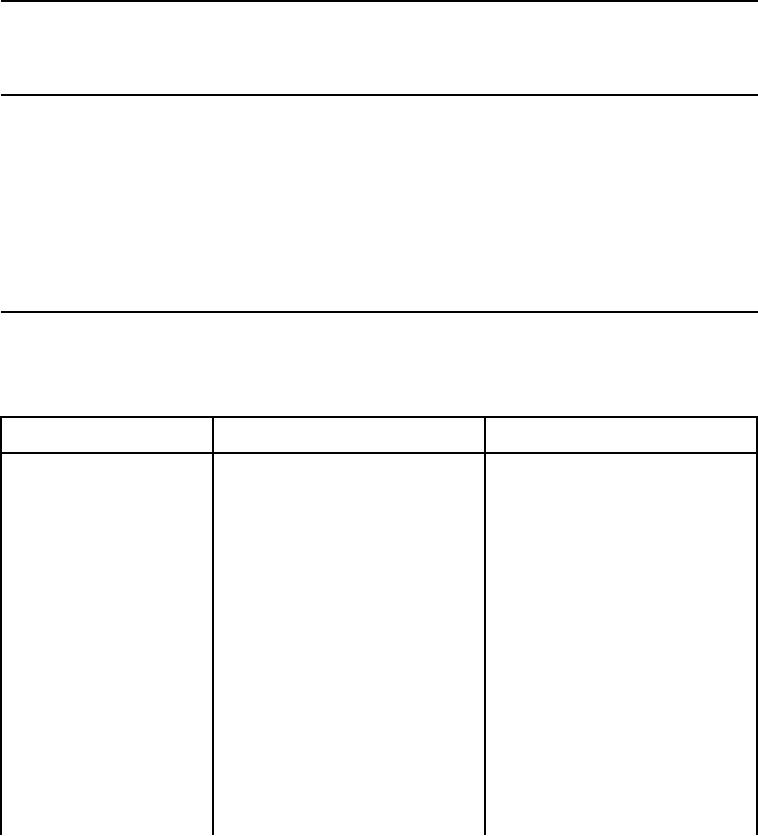

Table 1. Bent Track Shoes.

Test or Inspection

Corrective Action

Malfunction

Measure track shoe grouser

1.

If grouser height is less than

1.

Excessive Track

height for excessive wear.

0.39 in (10 mm), replace track

Shoe Grouser

Note measurement.

shoe(s). (Volume 3,

Wear.

WP 0391)

2.

If grouser height is greater than

0.39 in (10 mm), proceed to

Malfunction 2.

Visually inspect for loose or

1.

If track shoes are loose,

2.

Loose or Damaged

damaged track shoes (TM

remove loose track shoes and

Track Shoes.

5-3805-294-10). (Volume 5,

remove any debris between

track shoe and link. Reinstall

WP 0794)

track shoes. (Volume 3,

WP 0391)

2.

If track shoes are damaged,

replace track shoes. (Volume

3, WP 0391)

3.

If track shoes are not loose or

damaged, proceed to

Malfunction 3.

0005-1