TM 5-3805-294-23-1

0024

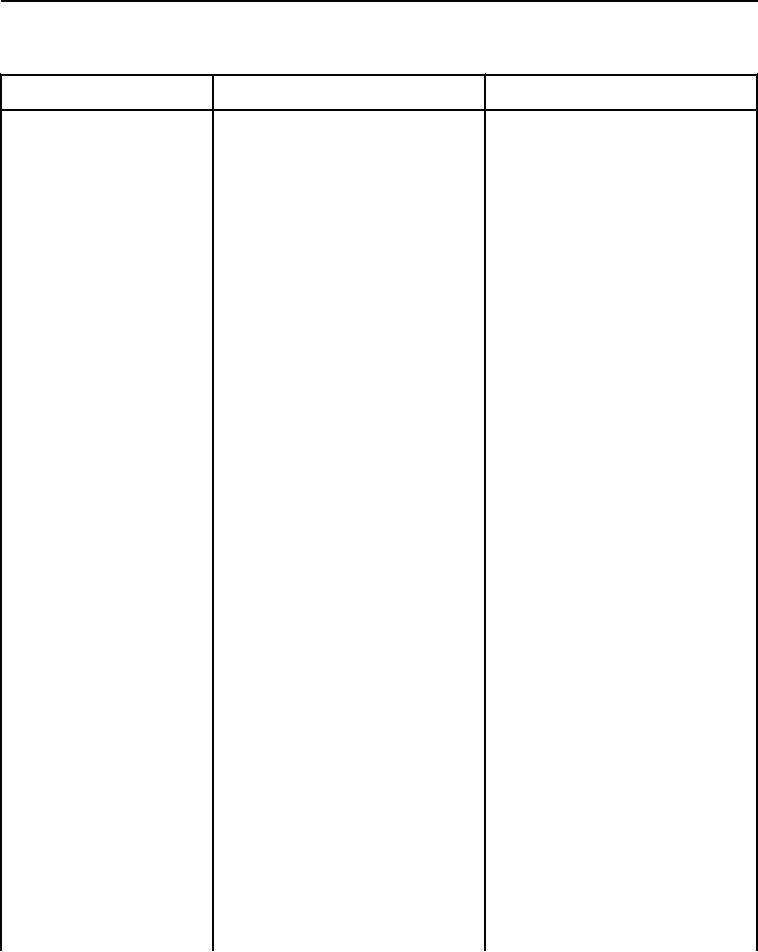

Table 1. DTC 100.31 - Engine Oil Pressure Detected With Engine Stopped - Continued.

Test or Inspection

Corrective Action

Malfunction

2.

Visually inspect engine oil

1.

If damaged or has loose pins,

pressure sensor for damaged

replace engine oil pressure

housing, damaged O-ring, and

sensor. (Volume 3, WP 0417)

loose pins. (Volume 5,

Restore machine to original

WP 0800, Figure 56)

condition and perform Harness

Diagnostic Mode Test.

(Volume 3, WP 0345)

2.

If not damaged and does not

have loose pins, proceed to

Malfunction 4.

Measure resistance (Volume

1.

If continuity is present,

4.

Open Circuit

proceed to Malfunction 5.

Between Engine

3, WP 0369) between engine

Wiring Harness

wiring harness connector P04

2.

If continuity is not present,

Connector P04

socket A (Volume 5,

replace engine wiring

Socket A and

WP 0800, Figure 56) and

harness. (Volume 4,

Ground.

known good ground. Note

WP 0510) Restore machine to

reading.

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

1.

Connect negative battery

5.

Engine Oil Pressure

Signal Wire Voltage

cable. (Volume 4, WP 0521)

Below 0.5 Volts.

2.

Turn key switch to ON position,

but DO NOT START ENGINE

(TM 5-3805-294-10). (Volume

5, WP 0794)

3.

Measure voltage (Volume 3,

WP 0369) between sockets A

and C on engine wiring

harness connector P04.

(Volume 5, WP 0800, Figure

56) Note reading.

4.

Turn key switch to OFF

1.

If less than 0.5 volts, replace

position (TM 5-3805-294-10).

engine oil pressure sensor.

(Volume 5, WP 0794)

(Volume 3, WP 0417) Restore

machine to original condition

and perform Harness

Diagnostic Mode Test.

(Volume 3, WP 0345)

2.

If greater than 0.5 volts,

proceed to Malfunction 6.

0024-3