TM 5-3805-294-23-1

0037

TROUBLESHOOTING PROCEDURE

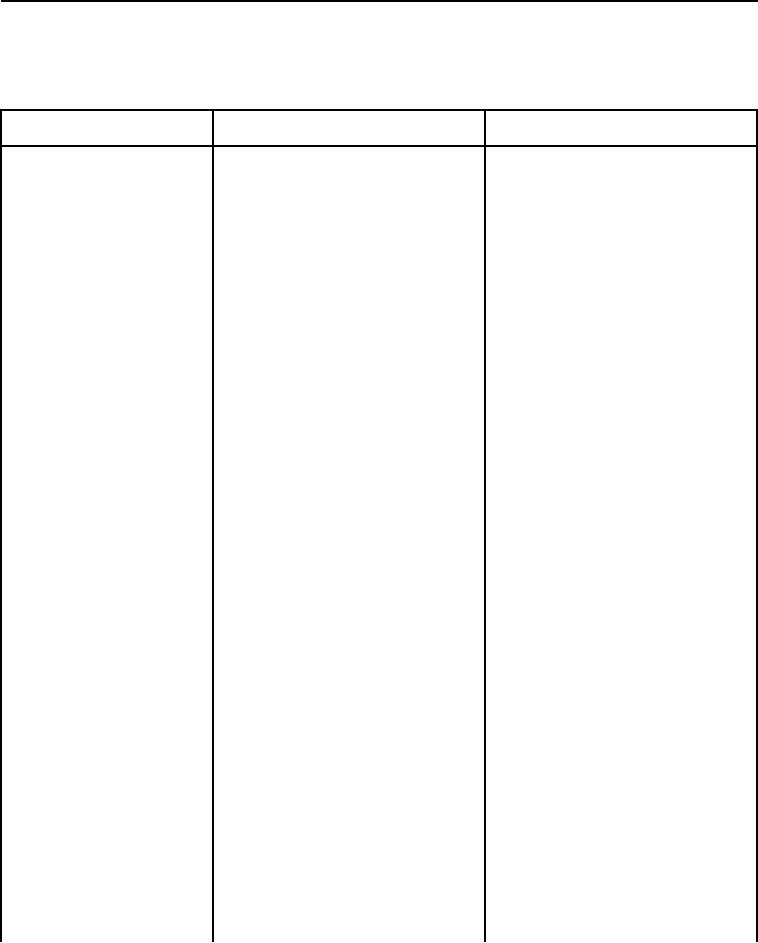

Table 1. DTC 157.03 - Fuel Rail Pressure Signal Out of Range High.

Test or Inspection

Corrective Action

Malfunction

1.

Disconnect engine wiring

1.

Engine Wiring

harness connector P05 from

Harness Connector

fuel rail pressure sensor.

P05 Has Damage or

Loose Sockets.

(Volume 5, WP 0800, Figure

57)

2.

Visually inspect engine wiring

1.

If damaged or has loose

harness connector P05 for

sockets, repair connector P05

damage or loose sockets.

(Volume 4, WP 0511) or

replace engine wiring

harness. (Volume 4,

WP 0510) Restore machine to

original condition and perform

Harness Diagnostic Mode

Test. (Volume 3, WP 0345)

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 2.

1.

Measure resistance (Volume

2.

Fuel Rail Pressure

Sensor

3, WP 0369) between pins 1

Measurement(s)

and 2 on fuel rail pressure

Out of

sensor. (Volume 5, WP 0800,

Specifications.

Figure 57) Note reading.

2.

Measure resistance between

pins 1 and 3 on fuel rail

pressure sensor. Note

reading.

3.

Measure resistance between

pins 2 and 3 on fuel rail

pressure sensor. Note

reading.

4.

Compare measurements with

1.

If within specifications,

below specifications:

proceed to Malfunction 3.

8 - 17 kohms between pins

2.

If not within specifications,

1 and 2.

replace fuel rail pressure

1 - 3 kohms between pins

sensor. (Volume 3, WP 0429)

1 and 3.

Restore machine to original

10 - 15 kohms between

condition and perform Harness

pins 2 and 3.

Diagnostic Mode Test.

(Volume 3, WP 0345)

0037-2