TM 5-2420-230-24-1

10-7. HYDRAULIC FLOW TESTING.

This Task Covers:

a. Testing

b. Follow-On Maintenance

INITIAL SETUP

Test Equipment

References

Flow meter, capable of measuring 30 gpm (114 L/min)

FO-4, Hydraulic schematic

Tools and Special Tools

Equipment Conditions

Pan, drain, Item 29, Appendix B

TM or Para

Condition Description

Tool kit, common no. 2, Item 36, Appendix B

Hydraulic system pressure

Tool kit, general mechanics, Item 38, Appendix B

released (engine access panel

Tool outfit, HSTRU, Item 40.1, Appendix B

left uninstalled).

Materials/Parts

Drawings Required

None

None

Personnel Required

Estimated Time to Complete

MOS 62B, Construction Equipment Repairer (2)

Refer to MAC in Appendix B

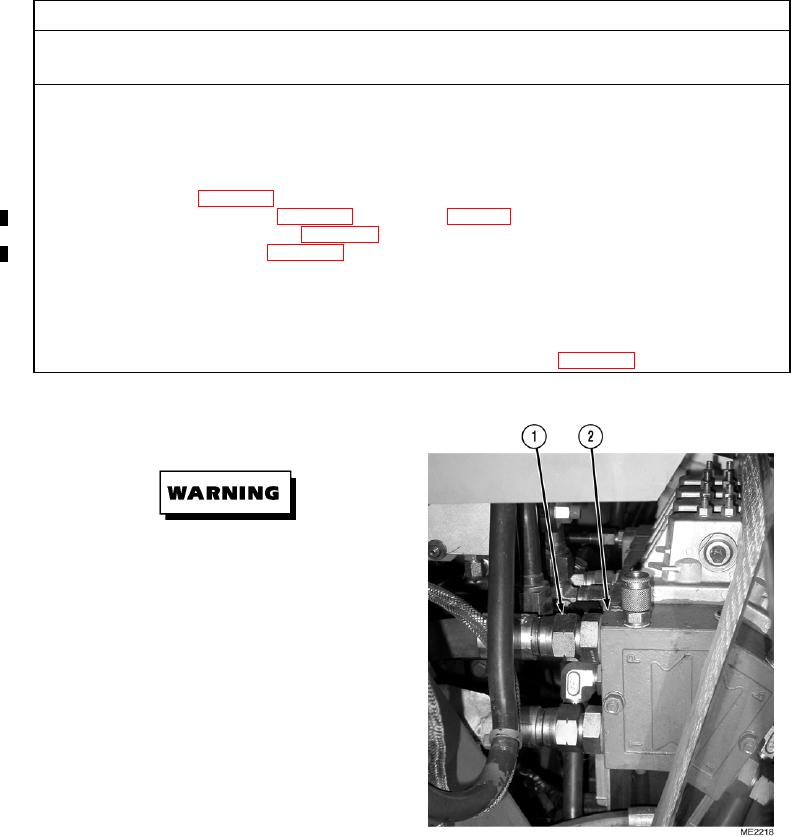

a. Testing.

(1)

Place drain pan beneath supply hose (1) and

FEL valve block (2)

Hydraulic fluid (Dexron III) is TOXIC.

Wear protective goggles and gloves; use

only in well-ventilated area; avoid contact

with skin, eyes, and clothes. Skin and

clothing that come in contact with

hydraulic oil should be washed

immediately. Saturated clothing should

be removed immediately. Failure to

comply may result in injury to personnel.

The IHMEE hydraulic system operates at

oil pressures up to 3,000 psi (20 680 kPa).

Never disconnect any hydraulic line or

fitting without first dropping system

pressure to zero. Failure to comply may

result in injury or death to personnel.

NOTE

Ensure no 90-degree elbows or hoses with

tight bends are used when connecting

flow meter.

Ensure suitable hoses and fittings are used when connecting flow meter.

(2)

Disconnect supply hose (1) from FEL valve block (2).

Change 1