TM 5-2420-230-24-1

d. Assembly.

Cleanliness is essential for correct and safe

operation of hydraulic system. Ensure dirt and

debris are not allowed to enter hydraulic

system. Failure to comply may result in

damage to equipment.

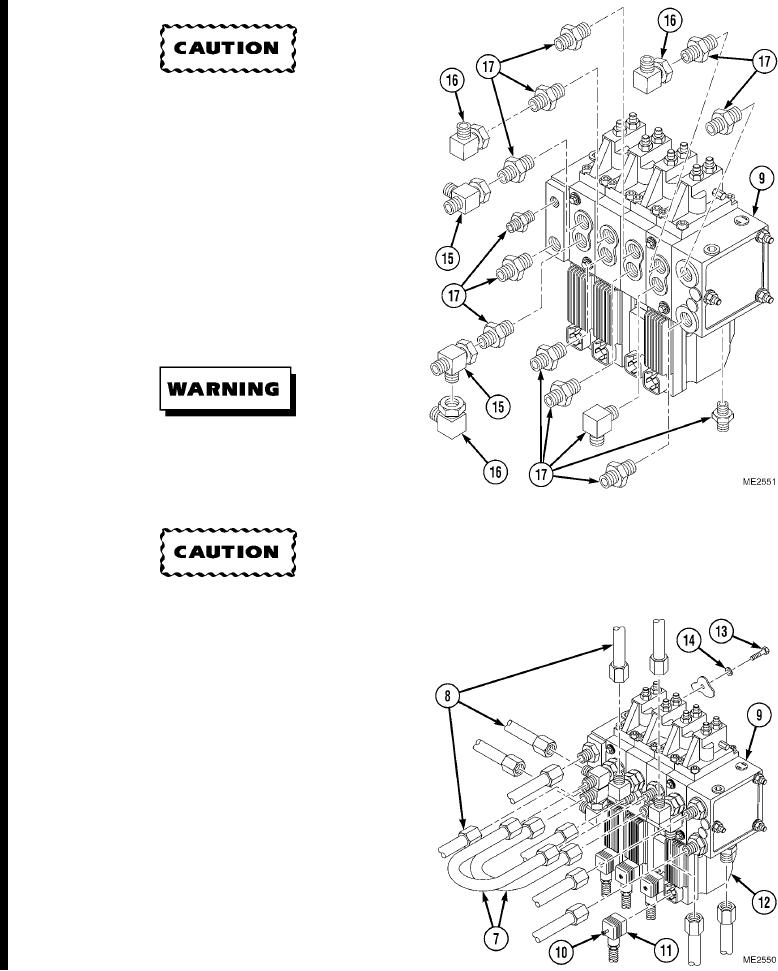

NOTE

Ensure all fittings are reinstalled to positions

noted prior to removal.

(1)

Install 13 fittings (17) in valve block (9).

(2)

Install two T-fittings (15) and three

elbows (16) on valve block (9).

e. Installation.

Valve block weighs 56 lb. (25 Kg). Use an

assistant and follow safe working procedures

when removing or installing valve block.

Failure to comply may result in injury to

personnel.

Cleanliness is essential for correct and safe

operation of hydraulic system. Ensure dirt and

debris are not allowed to enter hydraulic

system. Failure to comply may result in

damage to equipment.

NOTE

Ensure all hoses, tubes, and wires are

reconnected to positions noted prior to

removal.

Install cable ties as necessary.

(1)

With the aid of two assistants, one inside cab

and two positioning valve block (9) on

vehicle, install valve block with four new

lockwashers (14) and bolts (13).

(2)

Connect four plugs (11) to solenoid

valves (12) and install screws (10).

(3)

Install 11 hydraulic lines (8) and

2 U-tubes (7) on valve block (9).

Change 1

10-26