TM 5-2420-230-24-1

b. Disassembly.

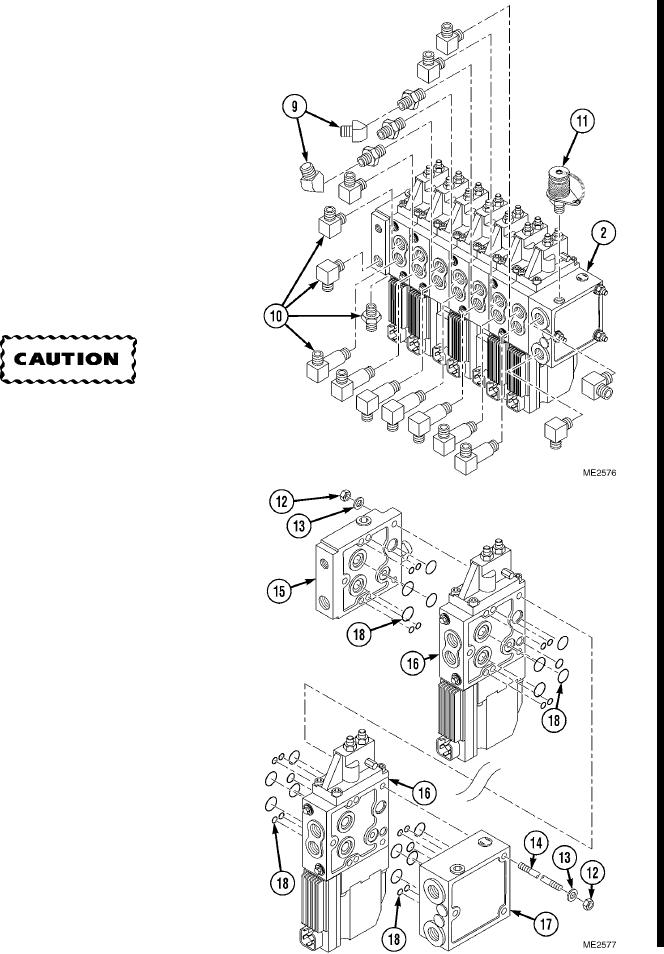

NOTE

Tag all fittings and note their positions

before removal.

Cap and plug all fittings and valve

openings upon removal.

(1)

Remove two elbows (9) from valve block (2).

(2)

Remove 18 fittings (10) from valve block (2).

Inspect O-rings on fittings. Replace any fitting

with a damaged O-ring.

(3)

Remove test port (11) from valve block (2).

c. Repair.

Cleanliness is essential for correct and safe

operation of hydraulic system. Ensure dirt and

debris are not allowed to enter hydraulic

system. Failure to comply may result in

damage to equipment.

NOTE

This task lists repair steps for entire valve

block; use steps as required.

Tag all valve bodies and note their

positions before removal. Ensure that valve

bodies are reassembled in order noted.

(1)

Remove six nuts (12), washers (13), and three

stems (14) from inlet section (15), seven valve

bodies (16), and outlet section (17).

(2)

Remove 71 O-rings (18) from between inlet

section (15), 7 valve bodies (16), and outlet

section (17). Discard O-rings.

10-29

Change 1