TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 28

FINAL ASSEMBLY

28.1

Refill drive head with oil (see lubrication section at front of manual for details of specification and

quantity).

28.2

Refit road wheels, securing with wheel nuts (1).Tighten nuts to 475 - 525 lbs. ft. (644 - 712 Nm).

Note :-

Interfaces must be free from dirt , including liner material debris, rust and paint.

Failure to keep interfaces clean, can and will cause brake drum to distort upon

tightening of wheel nuts. For further details see BS AU50 : Part 2 : Section 7A : 1995.

TP1148

Clean interfaces

Clean interfaces

Fig. No. 36

28.3

Remove axle supports, then lower vehicle to ground.

28.4

Remove chocks and jacks.

Note :-

At the axle build, tracking is set to TD 186/1 i.e 'Toe Out'. However, where part time all

wheel drive is used the axle should be re-aligned to 'Toe In' as below:-

28.5

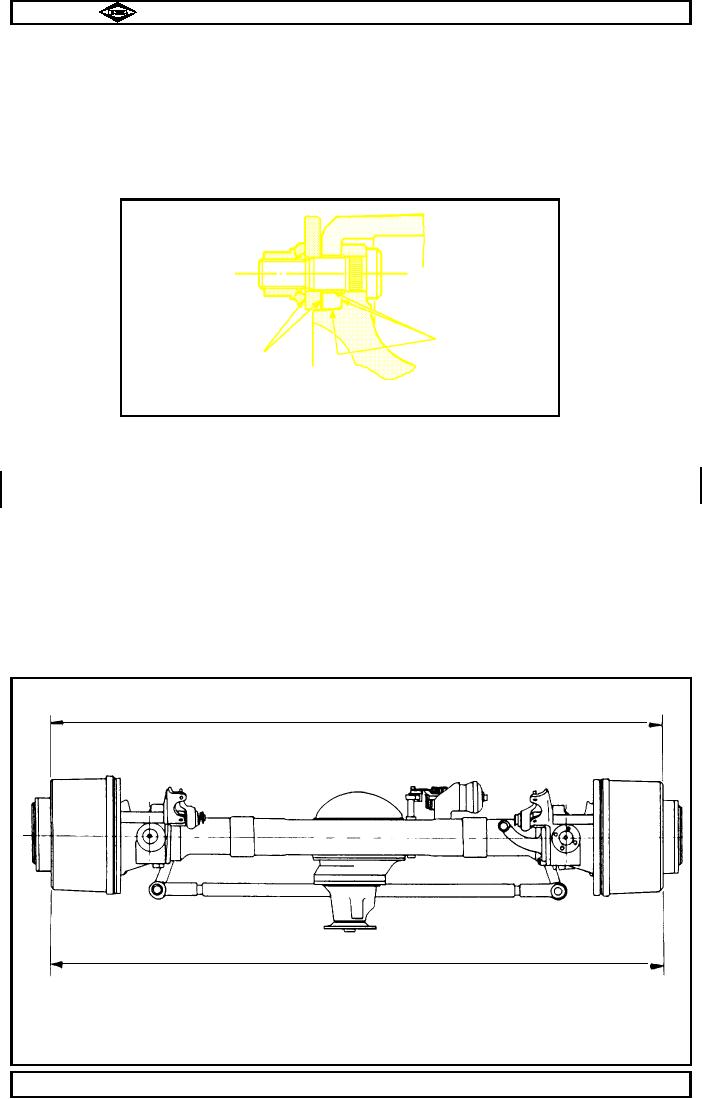

Check wheel alignment as follows :-

Set wheels in a straight ahead position, and at points level with wheel centre, measure distance

between edges of wheel rims both in front and behind axle centre.

For correct alignment front measurement (` A') shoul be 0" to 1/16 " smaller than that of rear (` B')

d

ie. toe -in. To allow for inaccuracies in wheels, same checks should be made with vehicle moved so that

wheels have moved a further half a revolution (see fig no. 37).

Adjust if required by slackening ball joint clamp bolts and rotating track rod tube.

DO NOT forget to re-tighten clamp bolts to 51 - 62lbs.ft. (69 - 84Nm.) after adjusting.

TP64

'A'

Front

'B'

Measure dimns. 'A '& 'B 'over brake drums

on horizontal centre line

To give correct alignment dimn 'A' should

be 1/16" smaller than dimn 'B'.

Fig No. 37

Manual No. 1785 Issue B

A

Page No.B32

Spicer Speciality Axle Division

J-62