TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 22

ASSEMBLY OF BALL SOCKET AND TIE ROD Cont.

Still with tool located on adjuster piece (17), back off carefully (LEAST AMOUNT) until adjuster piece

22.7

split pin (12) is allowed to pass throught body, and that ball pin shank can be moved by force of hand,

then remove tool.

Note :-

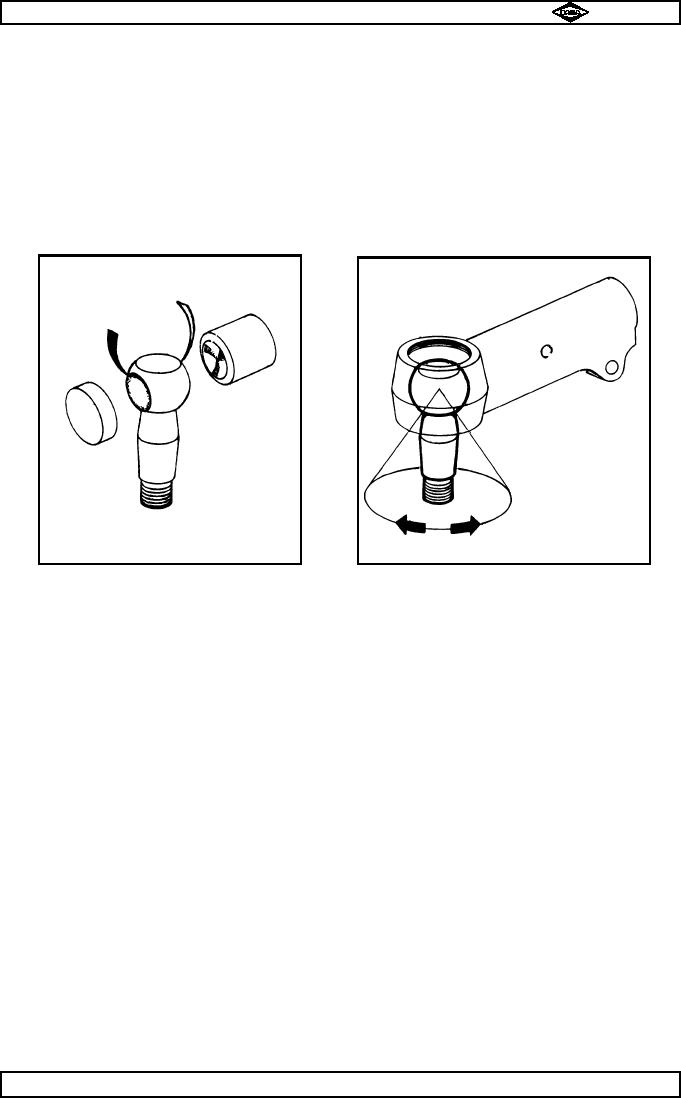

If ball pin (8) does not rotate when re-adjusted in line with above instructions, this

suggests that ball pin has local worn flats as shown in fig.no. 30 in this instance ball

pin (8), thrust cup (15) and rubbing pad (14) MUST be replaced, if not FAILURE could

occur in service, ie ball pin (8) not being able to move in assembly when turning from

lock to lock as shown in fig 31.

TP59

TP60

Local flats worn

here

Fig No. 30

Fig No. 31

Rotation.

22.8

Fit cover plate (9) into top of ball socket body, re-peen using a cold chisel to secure.

22.9

Screw assembled ball socket onto tie rod. Lining up marks on both body and tie rod previously made,

or retracking using manual Instructions.

22.10

Tighten pinch bolt (11) to 51 - 62lbs. ft. (69 - 84Nm.) to secure ball joint to tie rod.

22.11

Fit split pin (10) to lock pinch bolt nut (11).

22.12

Fit dirt seal (pressing) (5) and dirt seal (rubber) (4) onto ball pin (8).

22.13

Locate ball socket and tie rod assembly with steering lever, carefully align and fit ball pin ( 8) into hole in

steering lever.

Note :-

Ball pin and ballpin tapers in bottom steering levers must be clean, dry and free from

oil prior to assembly.

22.14

Fit pin washer (3) onto ball pin (8).

22.15

Screw pin nut ( 2) onto ball pin (8) then tighten to 100 lbs ft.(136Nm.) torque.

22.16

Using a 2lb hammer, tap steering lever to 'Shock' ball pin (8) into taper hole.

22.17

Re-torque pin nut (2) to 100 lbs ft.(136Nm).

22.18

Fit split pin (1), if slot / hole are not in line , adjust up to next slot.

Min pin nut torque 100 lbs ft.(136Nm.)

Max pin nut torque 170 lbs ft. (230Nm)

22.19

Re-charge ball socket with Shell Retinax LX or equivalent grease.

Manual No. 1785 Issue A

Page No.B27

Spicer Speciality Axle Division

J-57