TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 20

ASSEMBLY OF SWIVEL JAW AND AXLE STUB Cont.

20.6

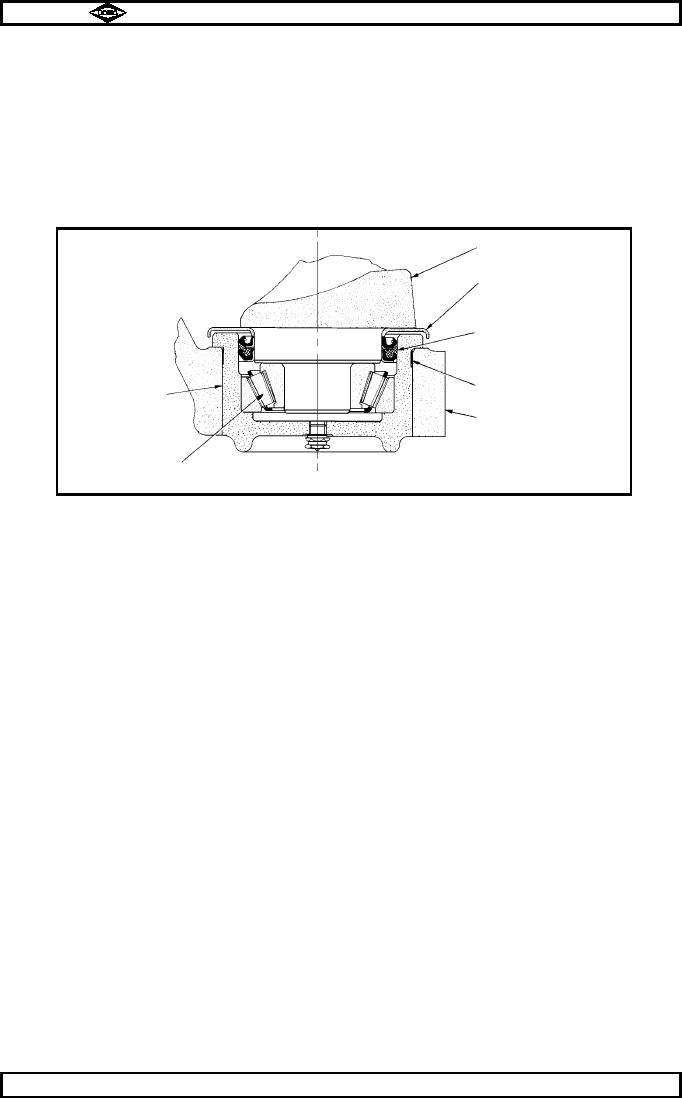

Fit swivel jaw bearing sleeve (146) into swivel jaw as follows:- (see fig no.25.).

a)

Ensure that surface of the swivel jaw bore and outer diameter of bearing sleeve are

de-greased, clean and dry.

b)

Coat undercut diameter of bearing sleeve with 'Loctite 638' to a bond line thickness of

0.007" to 0.009" (0.178 to 0.229 mm).

c)

Bearing housing (146) should then be inserted into swivel jaw (71) within 10 minutes of

Loctite being applied.

The cure cycle for 'Loctite 638" in average room temperature of 68F (20 C) is

d)

15 minutes for handling and 3 - 6 hours for full curing time.

TP55

Bottom swivel

Dirt excluder

Fill gap between oil

seals with grease

'Loctite 638' compound

Bearing housing

Swivel jaw

Pack bearing with

grease on assembly

Fig No. 25

20.7

Knock swivel jaw bush (75) into position using service tool no. E546.

20.8

Check swivel jaw / swivel stub studs (119) for misalignment and tightness re-fitting to procedure shown

on page B40.

20.9

Similarly, check brake bracket / swivel jaw / stub studs (117) for misalignment and tightness.

20.10

Assemble swivel jaw (71) and swivel stub (98) together ensuring that swivel jaw and stub are positioned

with stub bush having double cross-over grooves to bottom.

20.11

Fit nuts (116) and tighten to 95 - 115 lbs. ft. (128 - 156Nm.).

Manual No. 1785 Issue A

Page No.B22

Spicer Speciality Axle Division

J-52