TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 17

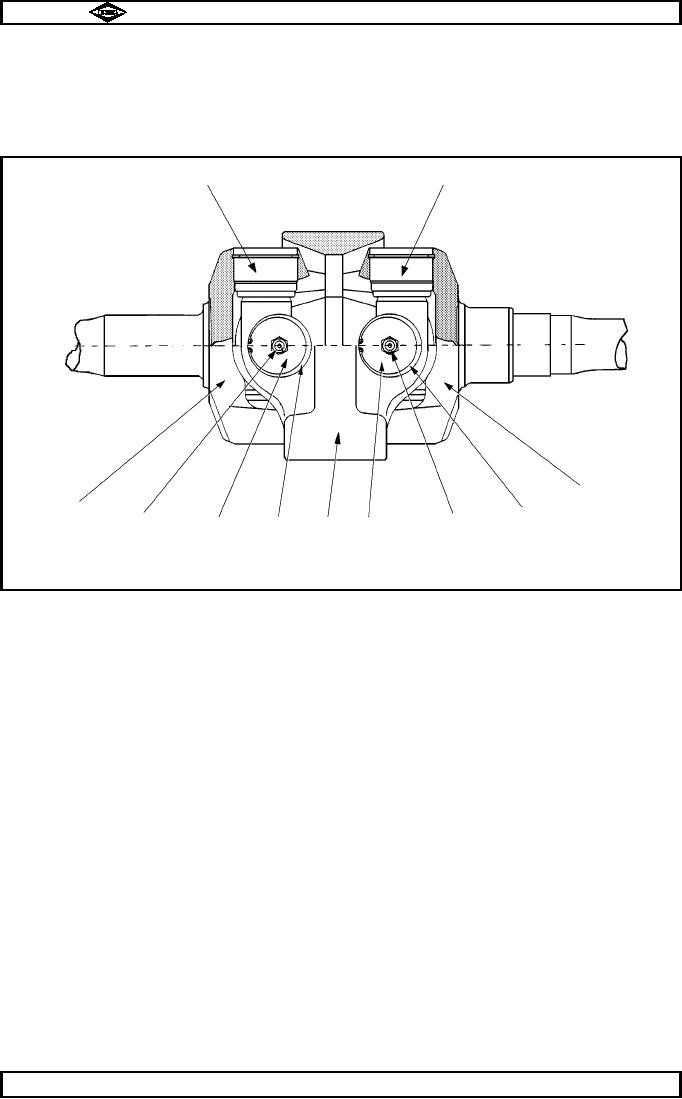

RE-ASSEMBLY OF DBM U.J. UNITS ( Fig. no.27)

Tooling and equipment required

a)

Light hydraulic / hand press.

b)

Copper hammer.

c)

Adequate rest to keep central housing horizontal during press operations.

TP1000

7

7

6

1

4

2

2

3

5

4

3

Fig. No.19

17.1

Press a bearing (3) half way into axle drive shaft fork (1 or 6).

17.2

Insert one end of a trunnion (7) into free hole (bottom) in fork (1 or 6) then pull up to locate in

bearing (3).

17.3

Press bearing (3) completely in until circlip (4) can be fitted.

17.4

Fit circlip (4) in its groove in fork (1 or 6) to secure assembly.

17.5

Turn assembly over and press second bearing (3) into position, lining it up with trunnion (7).

17.6

Fit circlip (4) in its groove in fork (1 or 6) to secure assembly.

17.7

Hold axle shaft assembly in your hand and lightly hit fork (1 or 6) a couple of times on side where

second bearing (3) was fitted to settle the unit parts.

17.8

Assemble other drive shaft parts as stated in 17.1 to 17.7.

17.9

When both axle shaft units are assembled, fit to central housing (5) as follows (Suggested two man

operation).

17.10

Hold central housing (5) with a cross hole at top then offer axle shaft unit with free end of trunnion (7)

lined up with hole, press a bearing half way into housing.

17.11

Lift up the axle unit into bearing (3) then press bearing fully home to allow circlip (4) to be fitted.

17.12

Turn the assembly over and fit second bearing (3) fully home and secure with circlip (4).

17.13

Tap the assembly gently with copper hammer to settle the unit parts.

17.14

Repeat operations 17.10 to 17.13 to fit other axle shaft unit to central housing (5).

17.15

Re-fit lubricators (2) and then charge the assembly with grease (Shell Retinax LX or equivalent).

Spicer Speciality Axle Division

Manual No. 1785 Issue A

Page No.B18

J-48