TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 25

SET THE HUB BEARING AS FOLLOWS :-

25.1

Fit pinch bolt (59) and nut (57).

25.2

Using service tool no. E399 fit hub nut (58) and tighten nut hard to take up bearing slack and to ensure

that annulus is fully home. Rotate hub and using a rawhide mallet, knock hub backwards and forwards

along axle arm to shock load and thus settle bearings into position.

Note :-

It is important to rotate and shock load the hub because :-

a) Rotation serves to ensure that bearing rollers settle in their correct tracks.

b) Shock load is to ensure that bearings are seated up to their shoulder

abutment, check tightness of axle tube nut (58) and if loose, re-tighten hard.

Rotate and shock load hub again.

Continue procedure until axle tube nut cannot be tightened after further rotating and shock loading hub.

Back off axle tube nut (58) by approx 1/16 " (20o) of a turn, then rotate and knock hub outwards along

25.3

axle arm to release bearings.

25.4

Tighten axle tube nut pinch bolt (59) to 30 - 34 lbs. ft. (41 - 46Nm.).

25.5

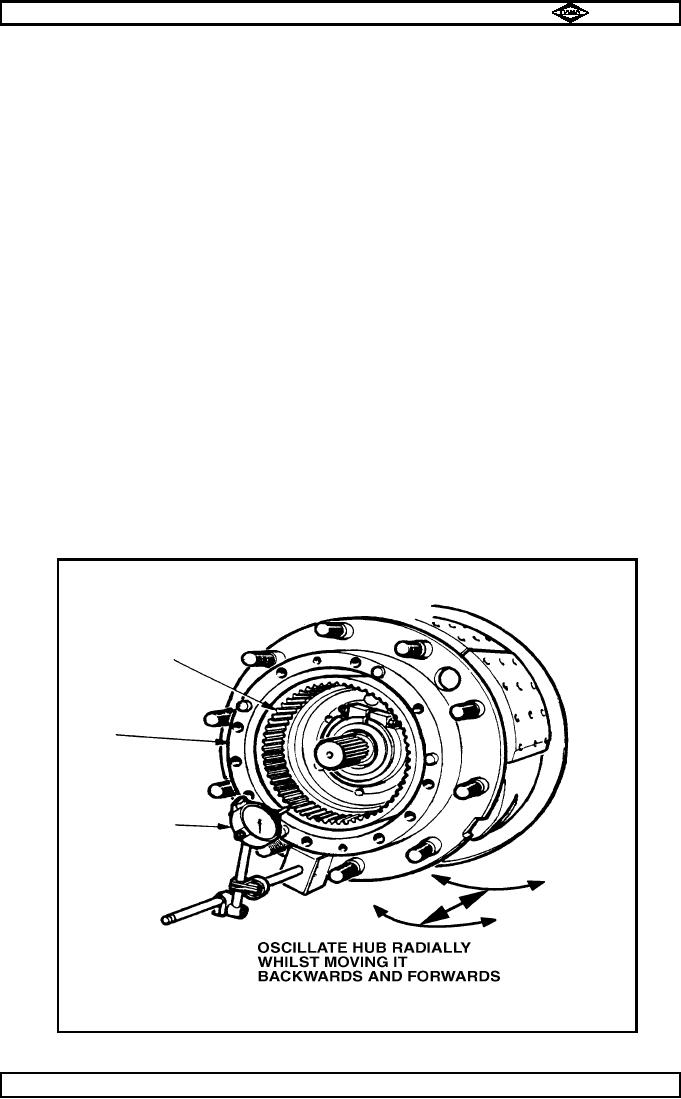

Mount a magnetic dial indicator on hub and position on end of annulus gear (14).

See fig. no. 33.

25.6

Oscillate hub backwards and forwards along axle arm and note variation shown by dial indicator

Permissable is between 0.0005" to 0.002" (0.013 to 0.051mm) movement (end float).

If end float is outside specified limits slacken pinch bolt (59) and reset axle tube nut (58) using above

procedure until correct setting is obtained.

TP62

Annulus gear

Hub

Dial indicator

Fig No. 33

Manual No. 1785 Issue A

Page No.B29

Spicer Speciality Axle Division

J-59