TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 10

FINAL ASSEMBLY OF PINION UNIT

10.1

Fit oil seal (26) into bearing housing (22) using a suitable fitting tool (tool no. E477 is available from our

spares and services dept. if required) as follows :-

a)

Seals must be fitted using a circular tool which bears on seal close to outside diameter

where casing is strongest. A correct fitting tool (E477) or one of similar design should be

used. Failure to use a suitable tool will result in distortion of seal casing, uneven wear of

lip and leakage. See fig. no. 4.

b)

Seals must remain square to bore during fitting. If seal cocks over and one side enters

bore first in will almost certainly result in distortion of casing which will not be corrected by

straightening up further down bore. Where possible, seals should be fitted under a press,

which reduces the likelihood of this problem.

c)

Seals must be truly square in bore after fitting. A cocked seal will act as an oil pump.

d)

When replacing a seal, always check coupling flange for damage in region polished by oil

seal lip : even slight damage in this area will cause leakage. Very slight marks may be

polished out with fine emery cloth, but it is essential that polishing marks are parallel to

seal lip. Where there is no more serious damage, it is permissable to fit two seals

back-to-back if there is room in housing, ie. outer seal with spring facing outwards, inner

seal with spring facing inwards. The outer seal acts as a spacer and ensures that inner

seal is fitted square and that it runs on a different part of coupling flange.

e)

Lips of seals or journals of coupling flanges should be smeared with clean gear oil prior

to assembly.

If seal is assembled dry it can burn out in a matter of minutes, before oil reaches it.

TP74

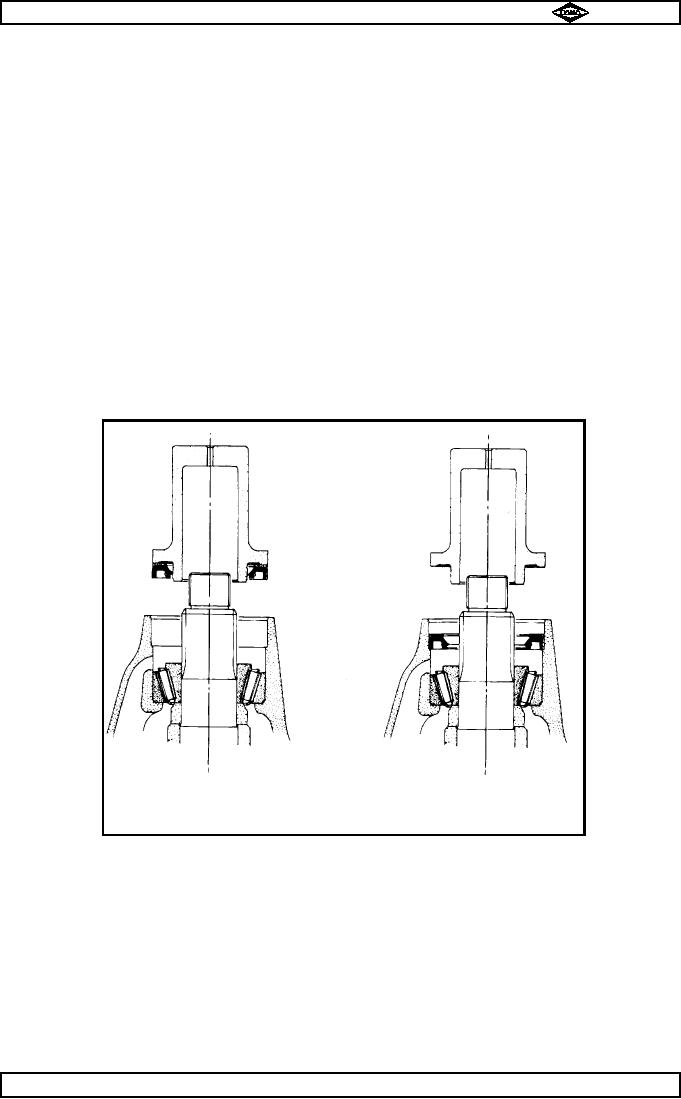

Seal being fitted direct into gear casing

Fig. No. 4

10.2

Refit coupling flange (27) and nut (28). Tighten nut to 800 - 900lbs.ft. (1085 - 1220Nm.).

10.3

Lock nut in position by peening locking flange into slot in pinion shaft.

10.4

If any pinion housing / gear casing studs (20) have been removed, renew and tighten to procedure

shown on page G23.

10.5

Place adjusting shim (21) into position on studs (20), then offer pinion assembly to gear casing (19),

tapping in position with a rawhide mallet.

Note :-

If new pinion / crownwheels are fitted, a nominal shim pack of 0.050 " (1.27mm) should

be fitted.

10.6

Secure in position with washer (23) and nuts (24). Tighten nuts progressively using diagonal selection,

until tightened to correct torque. 47 - 53 lbs ft (64 - 72 Nm).

Manual No. 1785 Issue A

Page No.E9

Spicer Speciality Axle Division

J-119