TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 12

INITIAL PREPARATION BEFORE FITTING ASSEMBLED SPIRAL BEVEL WHEEL

(CROWNWHEEL) AND DIFFERENTIAL

12.1

Secure pinion and casing assembly in a suitable diff. build stool.

12.2

Clean and deburr bevel casing legs (19) and bevel casing straps (12).

12.3

Fit bearing cups (14 & 44) into relevant half bores of bevel casing (19).

12.4

Check bevel casing strap studs (18), if any have been removed, replace then tighten to

88 - 98 lbs ft.(119 - 133Nm.).

12.5

Carefully fit bevel casing straps (12) down studs (18) to locate on bearing cups (14 & 44).

Check alignment of matching marks on bevel casing legs and straps (19 & 12) to ensure that straps are

not transposed, bearing cups (14 & 44) should rest snugly in bores.

Note :-

on no account should extra pressure e.g. hammer be used .

12.6

Fit diff. strap washers (11) and temporary plain nuts onto bevel casing strap studs (18) then tighten to

105 lbs ft. (142Nm.).

12.7

Fit bearing adjusting nuts (13 & 45) which should be free to turn with hand pressure only, if not, it may

be because of cross threading. Remove and deburr.

12.8

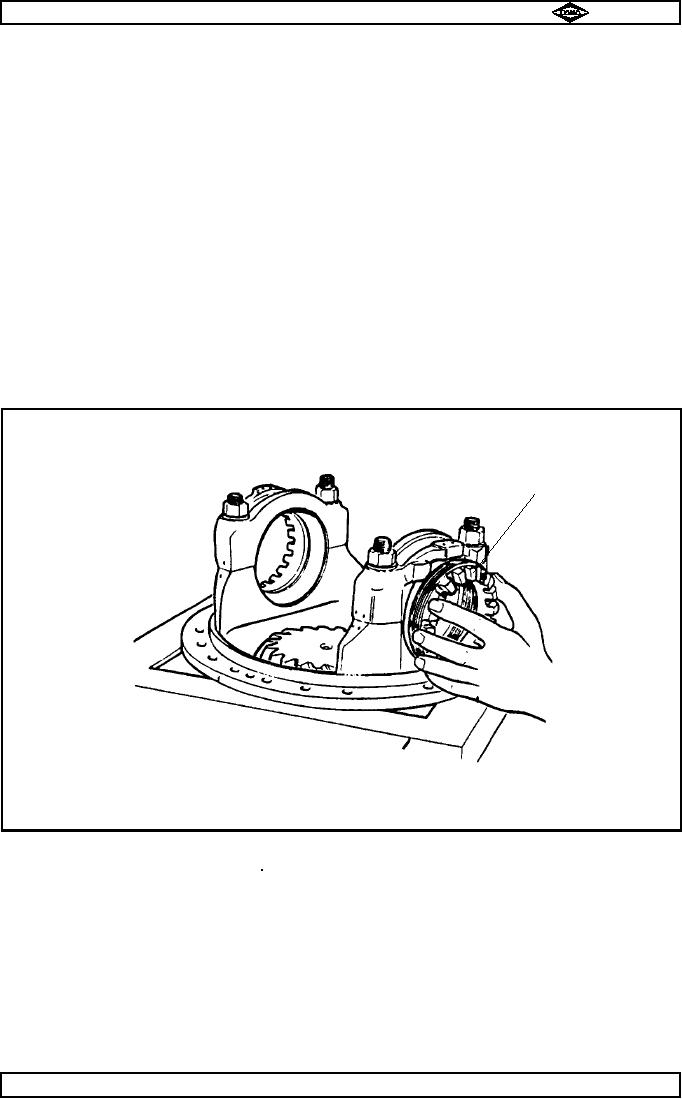

Check freedom of diff. bearing adjusting nuts (13 & 45) by unscrewing and refitting.

To assist this operation, tap bevel casing straps (12) lightly on top with a 2lb hammer. See fig. no. 5.

TP16

Diff bearing

adjusting nut (13 & 45)

●

Fig No. 5

12.9

Having checked fitting of adjusting nuts (13 & 45), remove bevel casing straps (12), bearing

cups (14 & 44) and adjusting nuts (13 & 45).

Manual No. 1785 Issue A

Page No.E11

Spicer Speciality Axle Division

J-121