TM 5-2420-230-24-2

Valve Clearance - Adjustment (0-103)

Section 0 - Engine Disassembly and Assembly - Group 00

Page 0-98

B Series Shop Manual

Feeler Gauge

Valve Stem to Rocker Lever Clearance

Intake Valve

Exhaust Valve

0.254 mm

0.508

[0.010 in]

[0.020 in]

The clearance is correct when some resistance can be

``felt'' when the feeler gauge is pulled through the space

between the valve stem and rocker lever.

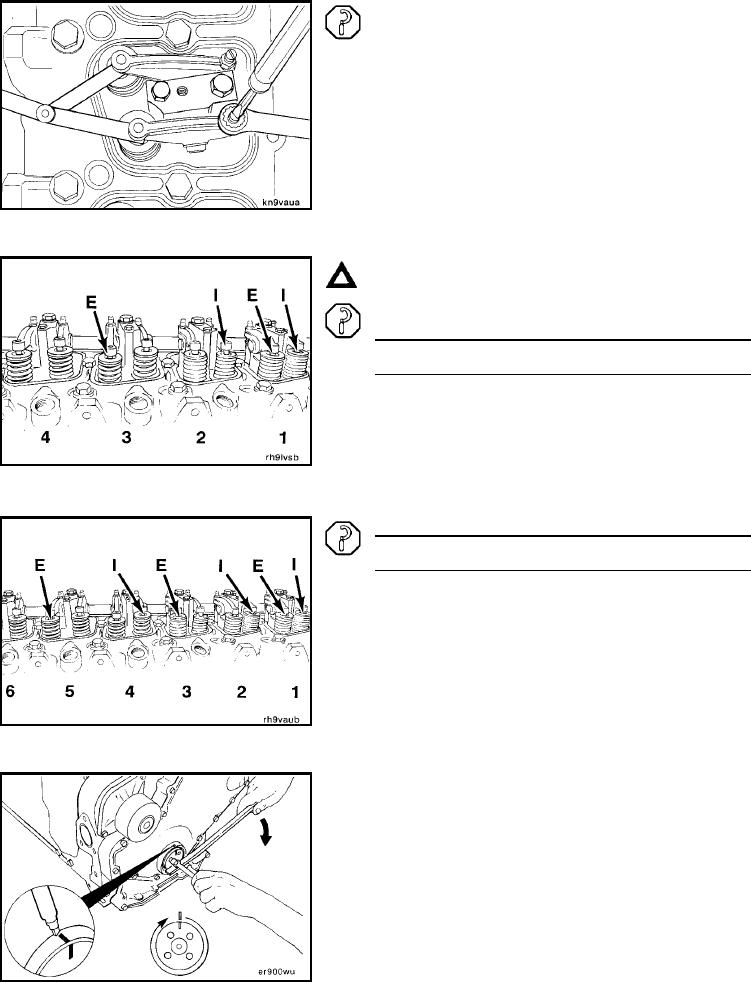

Adjust the valves as indicated in the following illustrations.

Tighten the locknuts and check the clearance again.

Torque Value: 24 Nm

[18 ft-lb]

Caution: Perform step A of the valve set procedure with

Cylinder Number 1 at TDC compression stroke (timing

pin will engage).

Step A - Four Cylinder

Valve

Cylinder

I = Intake

E=

Exhaust

1

*

*

2

*

-

3

-

*

4

-

-

(* = Set)

(- = Do not Set)

Step A - Six Cylinder

Valve

Cylinder

I = Intake

E = Exhaust

1

*

*

2

*

-

3

-

*

4

*

-

5

-

*

6

-

-

(* = Set)

(- = Do not Set)

Perform Step B of the valve set procedure with Cyl-

inder Number 1 at TDC plus 360 degrees (timing pin

will not engage).

Mark the crankshaft and front cover. Rotate the crankshaft

one full turn.

L-187