TM 5-2420-230-24-2

Section 1 - Cylinder Block - Group 1

Crankshaft Gear - Replacement (1-13)

B Series Shop Manual

Page 1-27

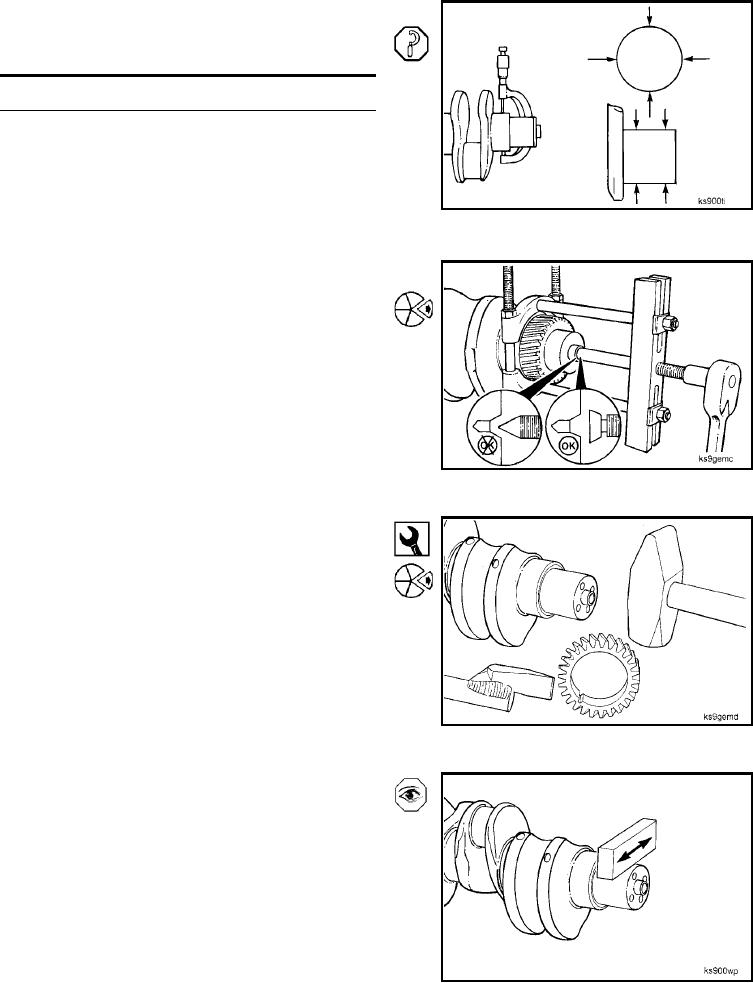

Determining Main Bearing Clearance

Measure the main journal diameters and determine main

bearing clearance.

Main Bearing Journal Diameter

mm

in

82.962

MIN

3.2662

83.013

MAX

3.2682

Out-of-Roundness: 0.050mm [0.002 in]

Taper: 0.013mm [0.0005 in]

Bearing Clearance = Main Bore Diameter with bearing

installed minus () Crankshaft Main Journal Diameter.

Maximum Bearing Clearance: 0.119mm [0.0047 in]

Crankshaft Gear - Replacement (1-13)

Remove the crankshaft gear.

Use a heavy duty puller.

2 lb Steel Hammer, Gear Splitter Part No. 3823585

An optional tool is available to split the crankgear off of

Pre-1991 crankshafts.

Service Tip: Always use a large steel hammer when split-

ting the crankshaft gear. Lead hammers absorb the shock

required to break the gear.

Remove all burrs and make sure the gear surface on the

end of the crankshaft is smooth.

L-230