TM 5-2420-230-24-2

B3.9 and B5.9 Series Engines

Flywheel (016-005)

Section 16 - Mounting Adaptations - Group 16

Page 16-11

Install the clutch discs, pressure plate, transmission, and

driveline (if equipped) in reverse order of removal. Refer to

the manufacturer's instructions.

NOTE: Align the universal joints on each end of the

driveshaft to prevent vibration.

Install (016-005-026)

NOTE: Use a new pilot bearing when installing a new or

rebuilt clutch.

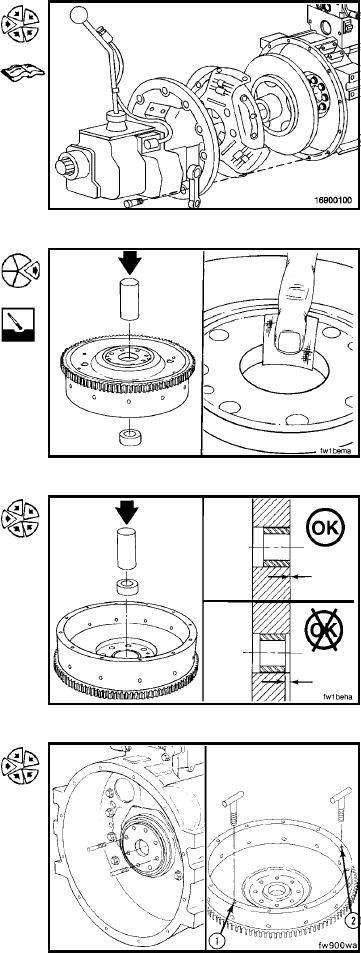

Use a mandrel and hammer to remove the pilot bearing.

Use a Scotch-BriteTM 7448, or equivalent, to clean the pilot

bore.

Use a mandrel and hammer to install the pilot bearing.

NOTE: The pilot bearing must be installed evenly with the

pilot bore surface.

Install two M12 x 1.25 x 90-mm guide pins into the crank-

shaft flange 180 degrees apart.

NOTE: If a clutch is used in the equipment, the threads in

the clutch pressure plate mounting capscrew holes can be

metric or standard. Be sure to use the correct capscrews.

Determine the capscrew thread design and size, and install

two t-handles into the flywheel (at points 1 and 2).

L-1339