TM 5-2420-232-10

0017

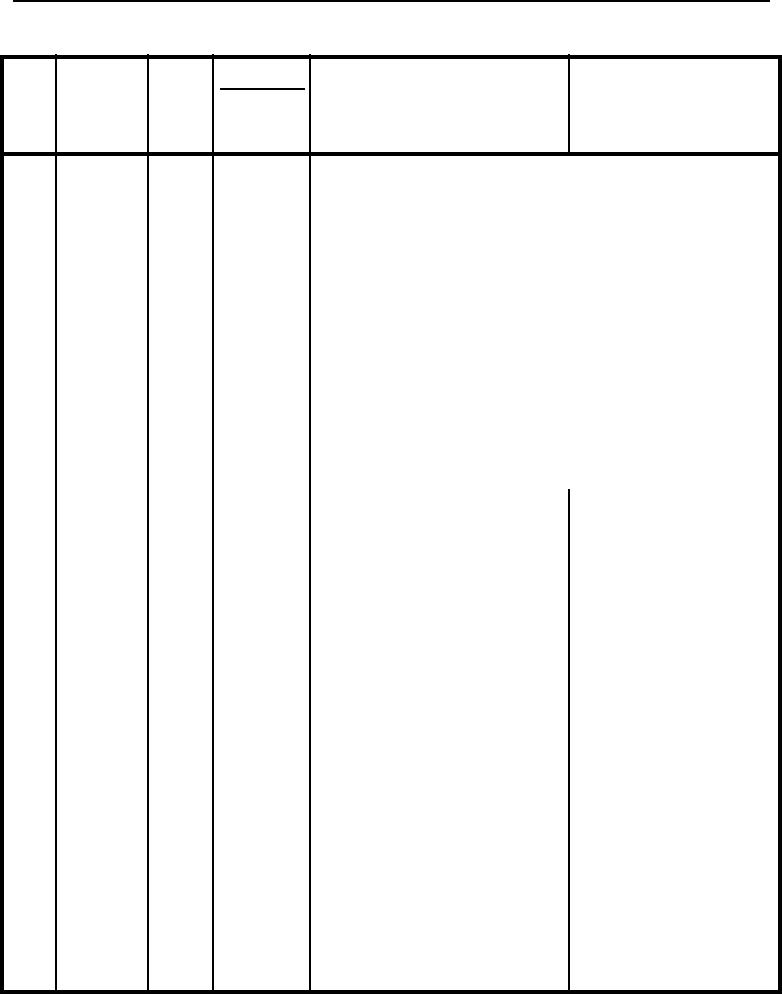

Table 4. Weekly/Annually PMCS.

LOCATION

ITEM TO

ITEM

NOT FULLY MISSION

CHECK/

MAN-

NO.

CAPABLE IF

PROCEDURE

SERVICE

INVERVAL HOURS

WARNING

1

Weekly

Batteries and

Cables

To avoid injury, eye protection and acid-resistant gloves must be worn

when working around batteries. Do not smoke, use open flame, make

sparks or create other ignition sources around batteries. If a battery is

giving off gases, it can explode and cause injury to personnel.

Remove all jewelry such as rings, ID tags, watches, and bracelets. If

jewelry or a tool contacts a battery terminal, a direct short will result

in instant heating, damage to equipment, and injury to personnel.

Sulfuric acid contained in batteries can cause serious burns. If battery

corrosion or electrolyte makes contact with skin, eyes, or clothing,

take immediate action to stop the corrosive burning effects. Failure to

follow these warnings may result in injury or death to personnel.

NOTE

For complete information on servicing batteries, refer to TM 9-6140-

200-14.

Perform service to all batteries.

a. Open the battery compartment access Hardware broken or damaged.

door.

b. If applicable, check the electrolyte

Electrolyte level is low or boiling.

level. Electrolyte level should be to the

ledge in battery filler opening (vent). If

low or boiling, notify Field Maintenance.

c. Check the connections are tight and

Cables or terminals are broken,

not corroded. If corroded or loose, notify loose, or heavily corroded.

Field Maintenance. Caps should be

screwed on tightly.

d. Check for cracked batteries. If

Battery is cracked.

cracked, notify Field Maintenance.

Open the brake reservoir compartment.

The level is below or above MIN

2

Weekly

Brake

Check for low fluid level or fluid leaks. or MAX marks on reservoir. Any

Reservoirs

The level should be between the MIN and brake fluid leak.

MAX marks. Report the need to con-

stantly top up fluid level to Field Mainte-

nance.

Check side rails, crossmembers, and

Obviously loose or broken side

3

Weekly

Frame

underbody supports for deteriorated bush- rails, crossmembers, bolts, or

ings, broken bolts, cracks, broken welds, welds.

or missing hardware.

a. Check wheels for damaged and

One or more missing wheel nuts

4

Weekly

Tires and

missing wheel nuts or studs. Ensure all

or studs.

Wheels

wheel nuts are tight.

Change 1

0017-22