TM 5-3805-280-24-2

Removal and Installation

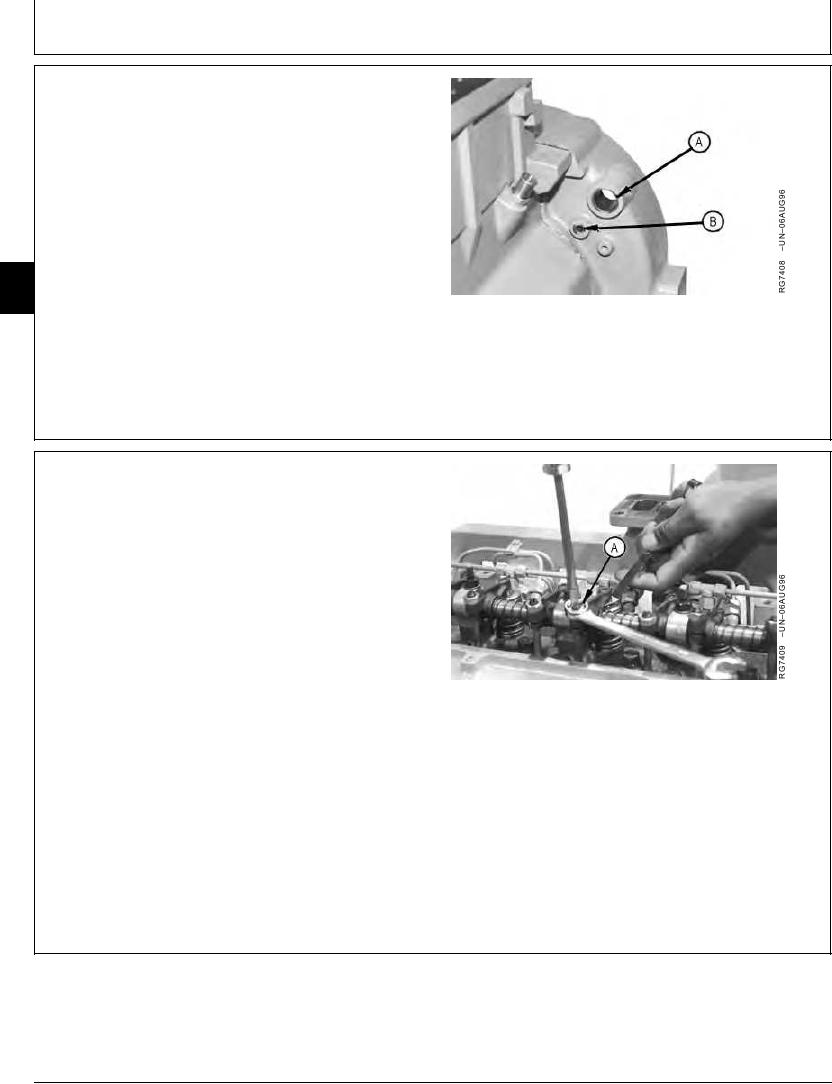

IMPORTANT: Visually inspect contact surfaces of

valve tips and rocker arm wear pads.

Check all parts for excessive wear,

breakage, or cracks. Replace parts that

show visible damage.

Rocker arms that exhibit excessive

valve clearance should be inspected

more thoroughly to identify damaged

parts.

04

0400

2. Remove plug (A). Install JDG820 Flywheel Turning

20

Tool. Remove cap screw (B). Install JDE81-4 Timing

A--Plug

Pin.

B--Cap Screw

TX,04,UU3877

1918SEP982/4

3. Turn flywheel until timing pin goes into hole in flywheel.

4. Using engine rotation tool, rotate engine flywheel in

running direction (clockwise viewed from front) until No.

1 cylinder is at "TDC" Compression stroke.

If No. 1 cylinder rocker arms are loose, the engine is at

No. 1 "TDC" Compression. If No. 1 cylinder rocker

arms are not loose, rotate engine one full revolution

(360) to No. 1 "TDC" Compression

To change piston position, remove timing pin and

rotate flywheel.

A--Jam Nut

5. Check and adjust valve clearance to specifications as

directed in the following procedures.

6. Loosen jam nut (A) and adjust clearance with a

screwdriver, as shown.

Continued on next page

TX,04,UU3877

1918SEP983/4

13-20