TM 5-3805-280-24-2

Fuel System

35

ADJUST NOZZLE OPENING PRESSURE

76

Close pressure gauge valve and flush nozzle by operating

pump rapidly.

Raise pressure on pump until nozzle opens (gauge drops

sharply).

Refer to nozzle opening pressure specifications below.

NOTE: In a few applications, RE60062 Nozzles (normally

used on aspirated engines), may be specified for

turbocharged (T or H) engines. In these cases,

use specifications listed below for naturally

aspirated (D) engines.

Refer to the following specifications for RE60062 nozzles

on naturally aspirated (D) engines:

Opening Pressure of New or Reconditioned Nozzle With New

Internal Parts--Specification

Opening Pressure For Setting .................. 24130--24480 kPa (241--244

bar) (3500--3550 psi)

Opening Pressure For Checking............. 21800 kPa (218 bar) (3160 psi)

(Minimum)

Minimum Acceptable Opening Pressure of Used Nozzle--

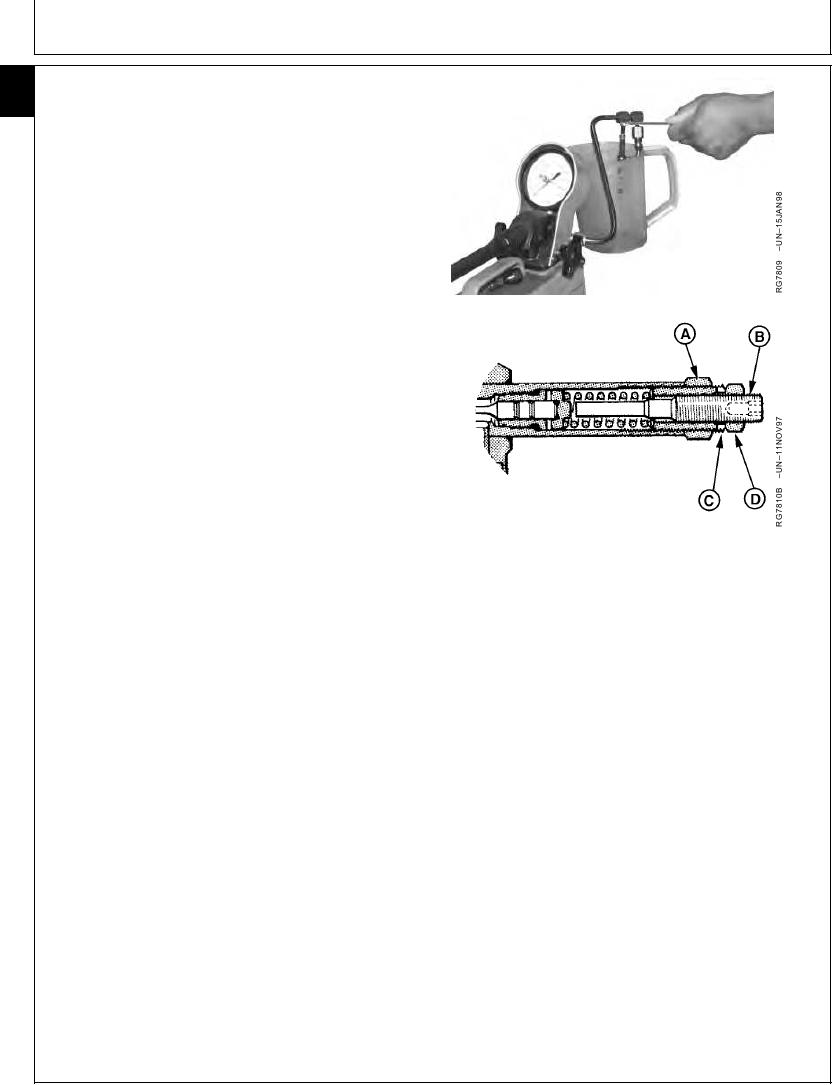

A--Pressure Adjusting Screw Lock Nut

Specification

B--Lift Adjusting Screw

C--Pressure Adjusting Screw

Opening Pressure For Checking............. 19850 kPa (198 bar) (2880 psi)

D--Lift Adjusting Lock Nut

(Minimum)

Maximum Opening Pressure Difference Between Cylinders--

Specification

Maximum Pressure Difference .......................... 700 kPa (7 bar) (100 psi)

Refer to the following specifications for RE48786 nozzles

on turbocharged (T or H engines):

Opening Pressure of New or Reconditioned Nozzle With New

Internal Parts--Specification

Opening Pressure For Setting .................. 25900--26200 kPa (259--262

bar) (3750--3800 psi)

Opening Pressure For Checking............. 25200 kPa (252 bar) (3660 psi)

(Minimum)

Continued on next page

RG,35,JW7631

1921NOV972/7

13-455