TM 5-3805-280-24-2

Fuel System

35

Hold pressure adjusting screw stationary while tightening

79

lock nut. Use ROS18958 Torque Wrench Adapter on

English-type lock nuts; No. 24374 on metric-type lock

nuts.

5. Tighten lift adjusting screw lock nut to specifications .

Fuel Injection Nozzle Lift Adjusting Screw Lock Nut--Specification

Torque .............................................................. 5 Nm (3.5 lb-ft) (42 lb-in.)

6. Recheck nozzle opening pressure.

If nozzle chatter is incorrect after servicing, valve parts

may be misaligned. To correct, screw pressure

adjusting screw through its range of adjustment several

times and reset valve lift. Recheck nozzle for chatter.

7. Clean nozzle with brass wire brush.

RG,35,JW7631

1921NOV977/7

INSTALL SEALS ON FUEL INJECTION

NOZZLE

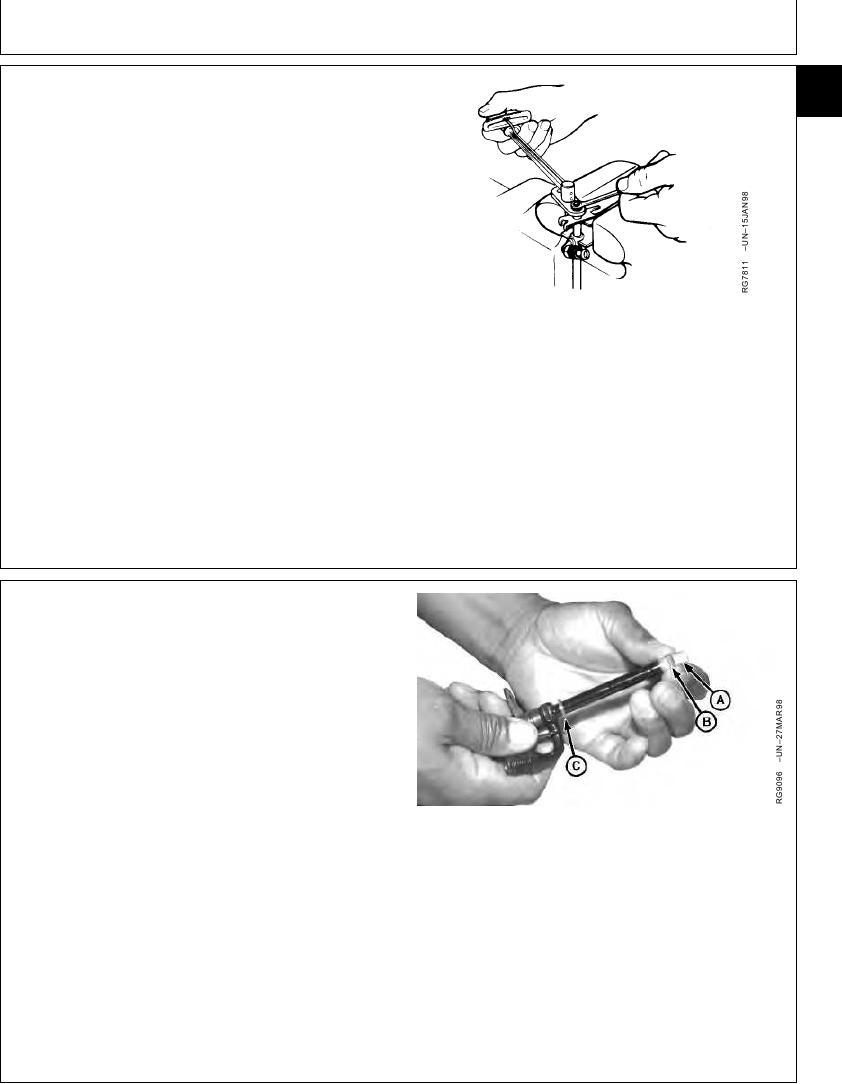

IMPORTANT: Each time an injection nozzle is

removed from the cylinder head,

replace carbon stop seal (B) with a new

one.

1. Position JD258 (ROS16477) Pilot Tool (A) over nozzle

tip.

2. Install a new seal washer (C) onto nozzle body.

A--Pilot Tool

3. Position a new carbon stop seal (B) on pilot tool. Slide

B--Carbon Stop Seal

the carbon seal until it seats in its groove on nozzle

C--Seal Washer

body.

NOTE: If nozzle is not going to be installed at this time,

install a No. 16189 Nozzle Protector Cap over

nozzle tip. Plug all other openings in nozzle to

prevent contamination.

RG,35,JW7586

1920NOV971/1

13-458