TM 5-3805-280-24-2

Starting Circuit Theory of Operation

TYPICAL STARTING MOTOR OPERATION

60

05

2

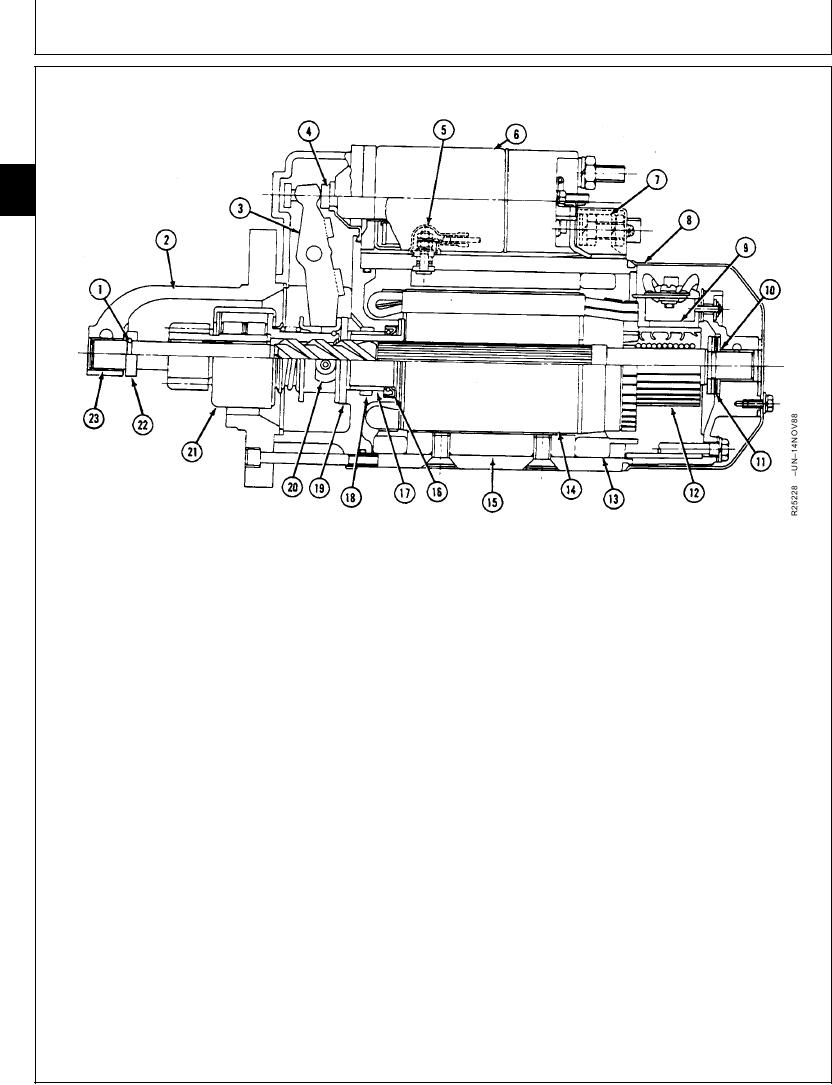

1--Snap Ring

7--Field Connector

13--Field Windings

19--Brake Washer

2--Drive End Housing

8--End Frame Cover

14--Armature

20--Wear Pads

3--Shift Lever

9--Brush

15--Pole Shoe

21--Overrunning Clutch

4--Plunger

10--Bushing

16--Oil Seal

22--Pinion Stop

5--Shunt Field Terminal

11--Thrust Washer

17--Bushing

23--Bushing

6--Solenoid Assembly

12--Commutator

18--Felt

The two windings cancel each other, and solenoid is

When solenoid (6) engages, it pulls shift lever (3). Shift

released.

lever pushes overrunning clutch drive (21) to engage

pinion in stater gear on flywheel. As armature (14)

A spring pushes solenoid back to disengaged position.

turns, it cranks engine.

This opens main contacts and shuts off current to field

windings and armature.

When engine starters, overrunning clutch spins freely

on shaft. This prevents overspeeding of armature by

Shift lever retracts overrunning clutch drive,

flywheel.

disengaging pinion from flywheel. Brake washer (19)

slows armature to a stop.

When key switch is released, current to solenoid

hold-in winding is shut off. Current can feed through

both pull-in and hold-in windings from main contacts,

but direction of current is reversed in pull-in winding.

RG,RG34710,2337

1915Mar971/1

16-82