TM 5-3805-281-24-2

Cylinder Head and Valves

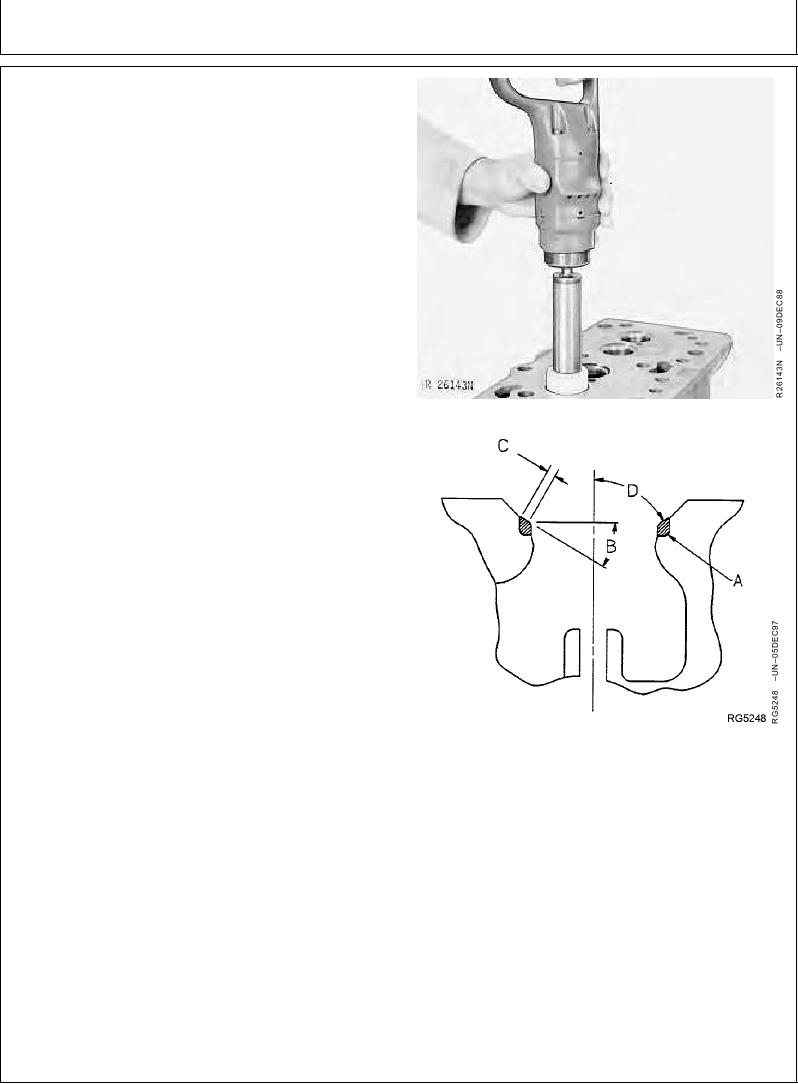

GRIND VALVE SEATS

IMPORTANT: Valve seat grinding should only be

done by experienced personnel familiar

with equipment and capable of

maintaining required specifications.

ALWAYS keep work area clean when

grinding valve seats. A 120-grit stone

MUST BE used for grinding both intake

and exhaust valve seat inserts (A).

Using JT05893 Heavy-Duty Seat Grinder

Set, grind valve seats to obtain correct

valve recess in cylinder head. (See

MEASURE VALVE RECESS earlier in

this group.) Be sure valve guide bores

are clean before grinding valve seats.

(See CLEAN VALVE GUIDES earlier in

Grinding Valve Seats

this group.)

If valve seats need grinding, only a few seconds are

required to recondition the average valve seat. Avoid the

tendency to grind off too much. Do not use excessive

pressure on the grinding stone.

1. Check the seat width (C) and contact pattern between

the seat and valve with bluing. Seat width MUST BE

maintained within specification. Use a vernier caliper or

scale to measure seat width. Thoroughly clean seat

area after grinding and replace valves and valve seat

inserts as necessary.

NOTE: Valve seat width can be reduced with a narrowing

stone. This will change the angle (B) at the top of

the seat and increase the diameter. If valve seat

width is too narrow, valve may burn or erode.

Measuring Valve Seats

Varying the width changes the fine contact

between valve face and seat.

A--Valve

Seat

Insert

B--Valve

Seat

Angle

2. ALWAYS measure valve seat runout after grinding

C--Valve

Seat

Width

using D11010KW Eccentrimeter and check recess in

D--Valve

Seat

Runout

cylinder head after grinding as described later.

Continued on next page

RG,RG34710,1093

1923OCT971/2