TM 5-3805-281-24-2

Cylinder Head and Valves

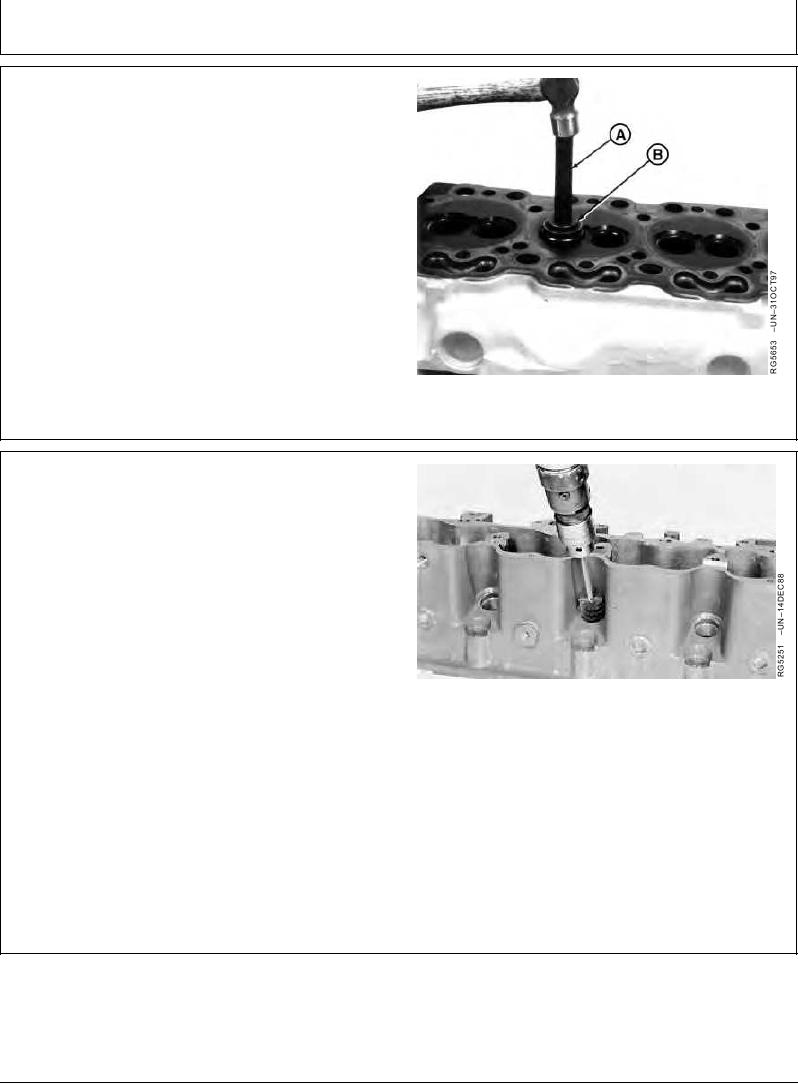

INSTALL VALVE SEAT INSERTS

1. Use the JDE7 Driver (A) along with JDG605 Valve

Seat Installer (B) to drive inserts into place. The larger

end of JDG605 Installer is used to install intake valves

and the smaller end is used to install exhaust valves.

2. Install new or refaced valves and check valve recess.

(See MEASURE VALVE RECESS, earlier in this

group.)

3. Grind valve seats as required to maintain correct valve

recess and valve-to-seat seal. (See GRIND VALVE

SEATS, earlier in this group.)

Installing Valve Seat Inserts

RG,RG34710,1095

1923OCT971/1

INSPECT AND CLEAN CYLINDER HEAD

NOZZLE BORE

1. Inspect condition of threads for gland nut. Threads are

metric (M28 x 1.5).

2. Inspect condition of nozzle seating surface in cylinder

head.

Cylinder head threads and nozzle seating surface must

be free of debris and carbon deposits.

Cleaning Cylinder Head Nozzle Bores

IMPORTANT: If the injection nozzle gland nut threads

are not clean, a false torque reading

may be obtained when the injection

nozzle is installed. This may prevent the

injection nozzle from seating properly in

the cylinder head.

3. Clean threads which have light foreign deposits using a

drill and the D17030BR Thread Cleaning Brush. Work

brush up and down several times to clean threads.

Continued on next page

RG,RG34710,1096

1923OCT971/3