TM 5-3805-294-23-1

0023

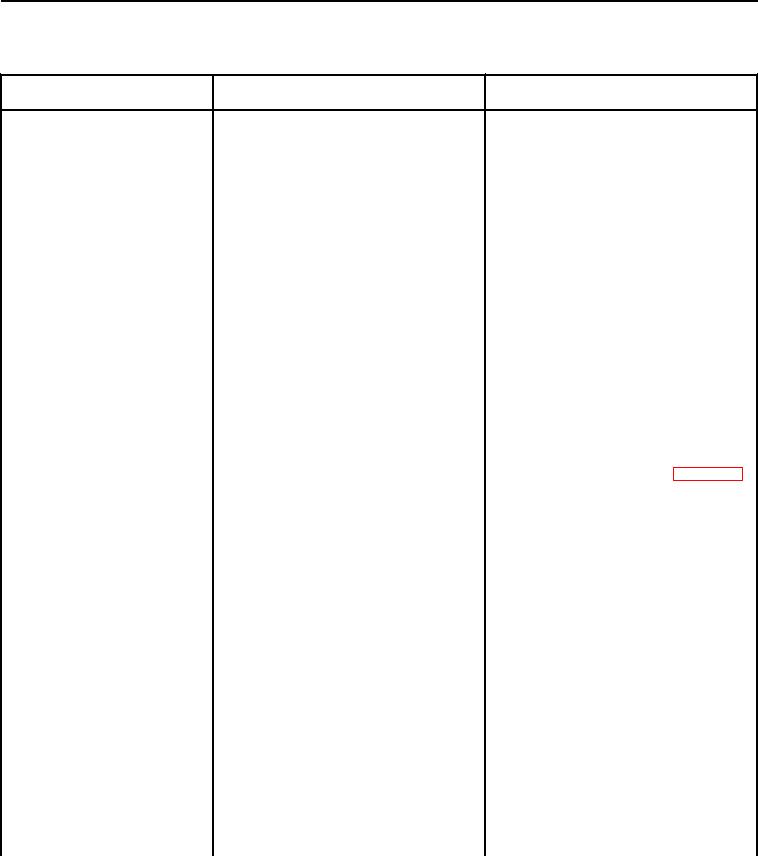

Table 1. DTC 100.18 - Engine Oil Pressure Signal Moderately Low - Continued.

Test or Inspection

Corrective Action

Malfunction

12.

Remove engine compartment

lower access cover. (Volume

4, WP 0593)

13.

Disconnect engine wiring

harness connector P04 from

engine oil pressor sensor.

(Volume 5, WP 0800, Figure

56)

14.

Remove engine oil pressure

sensor. (Volume 3, WP 0417)

15.

Perform engine oil pressure

1.

If engine oil gauge pressure

test with gauge. (Volume 3,

matches Service ADVISOR

reading, install engine oil

WP 0335)

pressure sensor. (Volume 3,

WP 0417) Discontinue this

troubleshooting procedure and

perform procedure for Engine

Oil Pressure Low. (WP 0122)

2.

If engine oil gauge pressure

does not match Service

ADVISOR value, proceed to

Malfunction 2.

Inspect connector P04 for

1.

If damaged or has loose

2.

Engine Wiring

damage and loose sockets.

sockets, repair connector P04

Harness Connector

P04 Has Damage or

(Volume 5, WP 0800, Figure

(Volume 4, WP 0511) or

Loose Sockets.

56)

replace engine wiring

harness. (Volume 4,

WP 0510) Restore machine to

original condition and operate

engine through normal speed

and load (TM 5-3805-294-10).

(Volume 5, WP 0794) Clear

and refresh DTCs. (Volume 3,

WP 0362)

If not damaged and does not

2.

have loose sockets, proceed to

Malfunction 3.

0023-3