TM 5-3805-294-23-1

0123

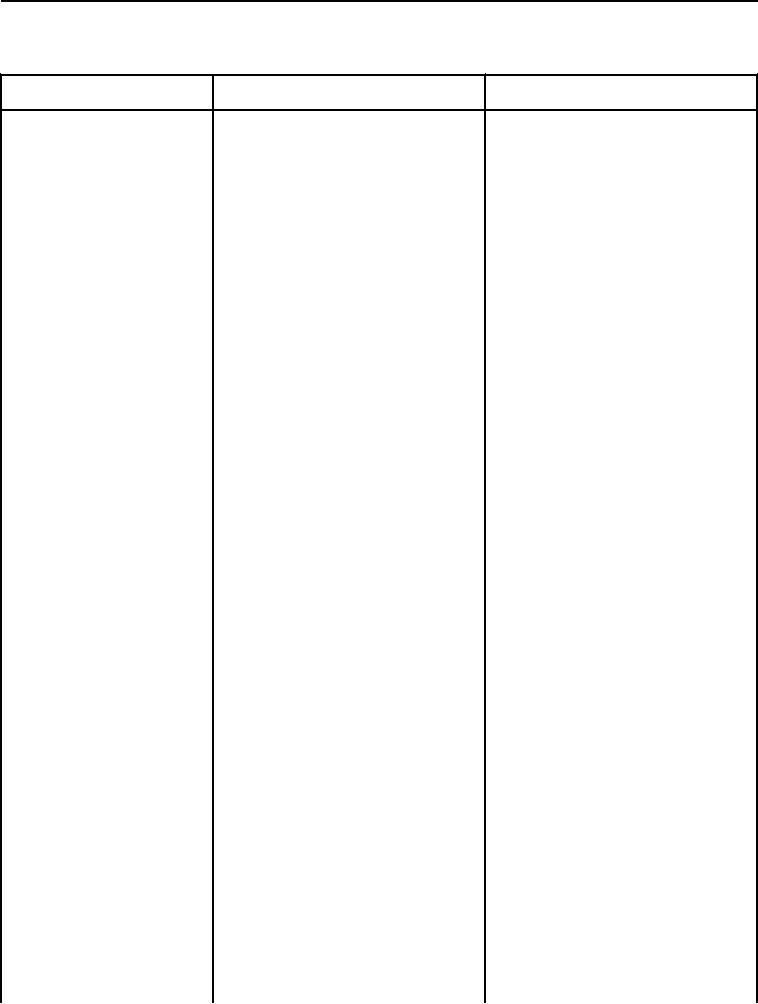

Table 1. Engine Will Not Crank - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect starter

1.

If damaged or has loose

33.

Starter Protection

protection relay K35 connector

sockets, replace starter

Relay K35

for damage and loose

protection wiring harness.

Connector Has

Damage or Loose

sockets. (Volume 5, WP 0800,

(Volume 4, WP 0528) Restore

Sockets.

Figure 213)

machine to original condition.

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 34.

With the aid of an assistant and

1.

If continuity is present,

34.

Open Circuit

using a jumper wire, measure

proceed to Malfunction 36.

Between Relay K4

resistance (Volume 3,

Socket 4 and Relay

2.

If continuity is not present,

K34 Socket G01.

WP 0369) between relay K4

proceed to Malfunction 35.

socket 4 (Volume 5, WP 0800,

Figure 186) and relay K34

socket G01. (Volume 5,

WP 0800, Figure 212) Note

reading.

With the aid of an assistant and

1.

If continuity is present, replace

35.

Open Circuit

using a jumper wire, measure

starter protection wiring

Between Relay K4

resistance (Volume 3,

harness. (Volume 4,

Socket 4 and Relay

K35 Socket 3.

WP 0369) between relay K4

WP 0528) Restore machine to

original condition.

socket 4 (Volume 5, WP 0800,

Figure 186) and relay K35

2.

If continuity is not present,

socket 3. (Volume 5,

replace starter protection

WP 0800, Figure 213) Note

wiring harness. (Volume 4,

reading.

WP 0528) Restore machine to

original condition.

1.

Install right-hand console

36.

Relay K4 Socket 2 is

switch panel. (Volume 4,

Grounded.

WP 0525)

2.

Turn key switch to ON position,

but DO NOT START ENGINE

(TM 5-3805-294-10). (Volume

5, WP 0794)

3.

Measure resistance (Volume

3, WP 0369) between relay K4

socket 2 (Volume 5, WP 0800,

Figure 186) and a known good

ground. Note reading.

4.

Turn key switch to OFF

1.

If continuity is present,

position (TM 5-3805-294-10).

proceed to Malfunction 37.

(Volume 5, WP 0794)

2.

If continuity is not present,

proceed to Malfunction 44.

0123-14