TM 5-3805-294-23-1

0123

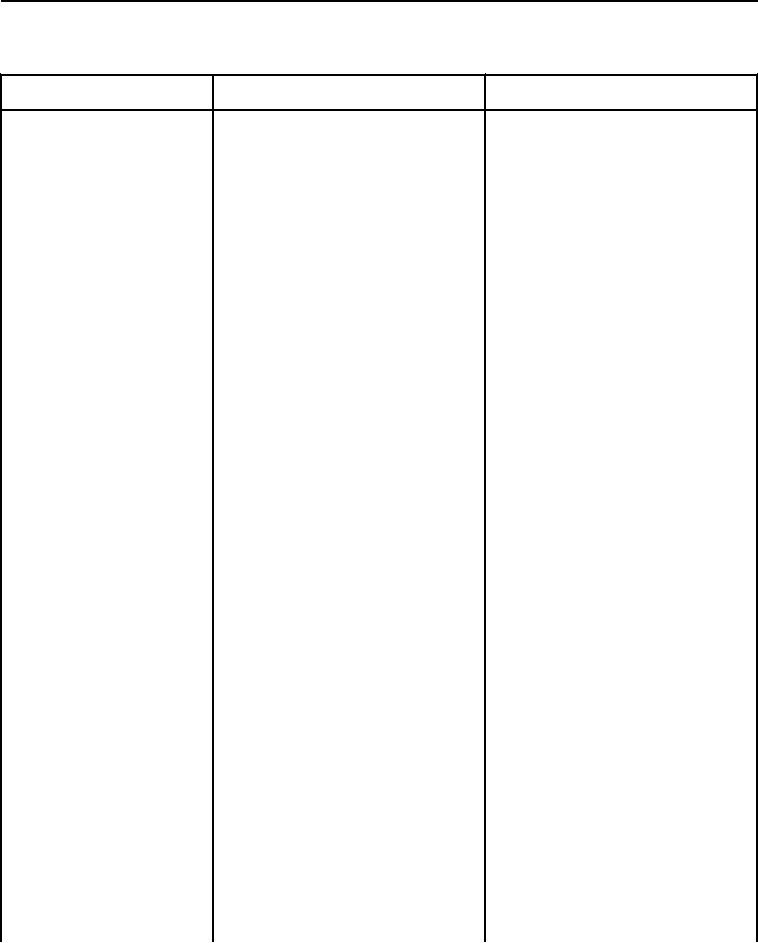

Table 1. Engine Will Not Crank - Continued.

Test or Inspection

Corrective Action

Malfunction

3.

Turn key switch to OFF

1.

If within 2 volts of battery

position (TM 5-3805-294-10).

terminal voltage, proceed to

Malfunction 26.

(Volume 5, WP 0794)

2.

If not within 2 volts of battery

terminal voltage, discontinue

this troubleshooting procedure

and perform procedure for Key

Switch Does Not Operate.

(Volume 2, WP 0169)

1.

Remove cab rear tray.

26.

Relay K4 Has

Damage or Loose

(Volume 4, WP 0566)

Pins.

2.

Remove relay (Volume 4,

WP 0503) K4 (Volume 5,

WP 0800, Figure 187) from

relay block.

3.

Visually inspect relay K4 for

1.

If damaged or has loose pins,

damage and loose pins.

replace relay K4. (Volume 4,

WP 0503) Restore machine to

original condition.

2.

If not damaged and does not

have loose pins, proceed to

Malfunction 27.

Perform relay test (Volume 3,

1.

If failed test, replace relay K4.

27.

Relay K4 Does Not

Ohm Out Properly.

WP 0365) on relay K4.

(Volume 4, WP 0503) Restore

machine to original condition.

(Volume 5, WP 0800, Figure

187)

If passed test, proceed to

2.

Malfunction 28.

Visually inspect relay K4

1.

If damaged or has loose

28.

Relay K4 Sockets

sockets for damage and loose

sockets, replace cab wiring

are Damaged or

sockets. (Volume 4,

harness. (Volume 4,

Loose.

WP 0503)

WP 0504) Restore machine to

original condition.

2.

If not damaged and does not

have loose sockets, proceed to

Malfunction 29.

1.

Disconnect connector X47.

29.

Connector X47 Has

Damage or Loose

(Volume 5, WP 0800, Figure

Sockets/Pins.

107)

0123-12