TM 5-3805-294-23-1

0130

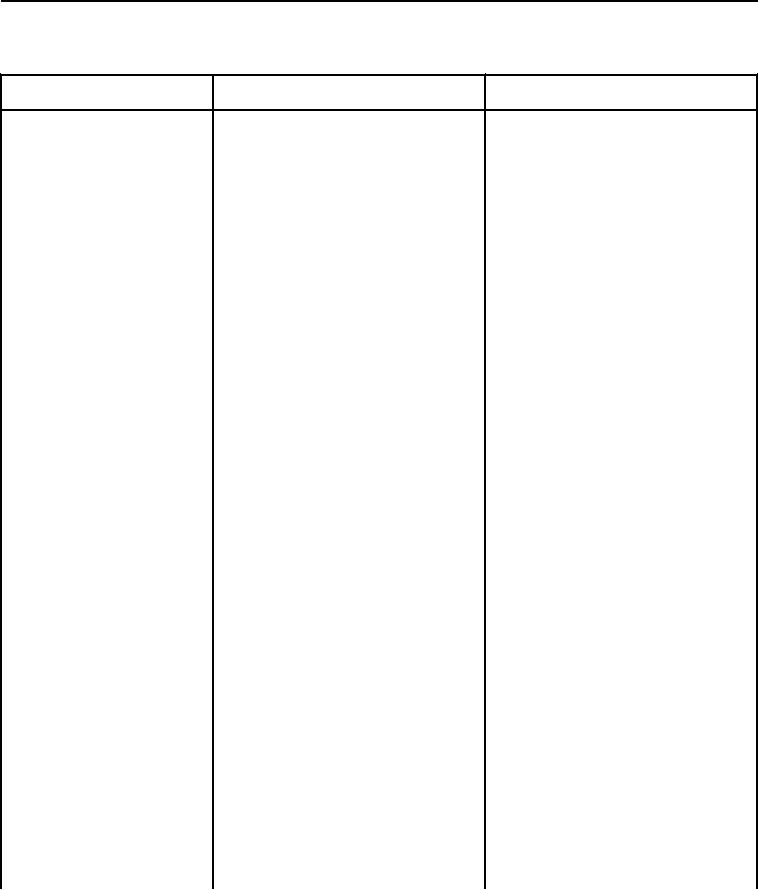

Table 1. High-Pressure Fuel Supply System Test - Continued.

Test or Inspection

Corrective Action

Malfunction

9.

Monitor Fuel Rail Pressure

while cranking engine(TM

5-3805-294-10). (Volume 5,

WP 0794) Pressure should be

2,900 psi (20 MPa) or above.

Note reading.

10.

When finished monitoring,

select Readings and select

Disconnect From Model(s).

(Volume 3, WP 0363)

11.

Select Yes to terminate your

readings connection. (Volume

3, WP 0363)

12.

Turn key switch to OFF

1.

If readings are within

position (TM 5-3805-294-10).

specifications, problem

corrected. Restore machine to

(Volume 5, WP 0794)

original condition. Clear and

refresh DTCs. (Volume 3,

WP 0362)

2.

If readings are not within

specifications, replace fuel

injectors (Volume 3,

WP 0408), then proceed to

Malfunction 5.

1.

Disconnect engine wiring

14.

Fuel Rail Pressure

harness connector P05 from

Sensor Check.

fuel rail pressure sensor.

(Volume 5, WP 0800, Figure

57)

2.

Turn key switch to ON position,

1.

If engine started, proceed to

START ENGINE (TM

Malfunction 15.

5-3805-294-10). (Volume 5,

2.

If engine did not start, proceed

WP 0794)

to Malfunction 22.

1.

Disconnect engine wiring

15.

Engine Wiring

harness connector J03.

Harness Connector

J03 Has Damage or

(Volume 5, WP 0800, Figure

Loose Sockets.

48)

0130-8