TM 5-3805-294-23-1

0130

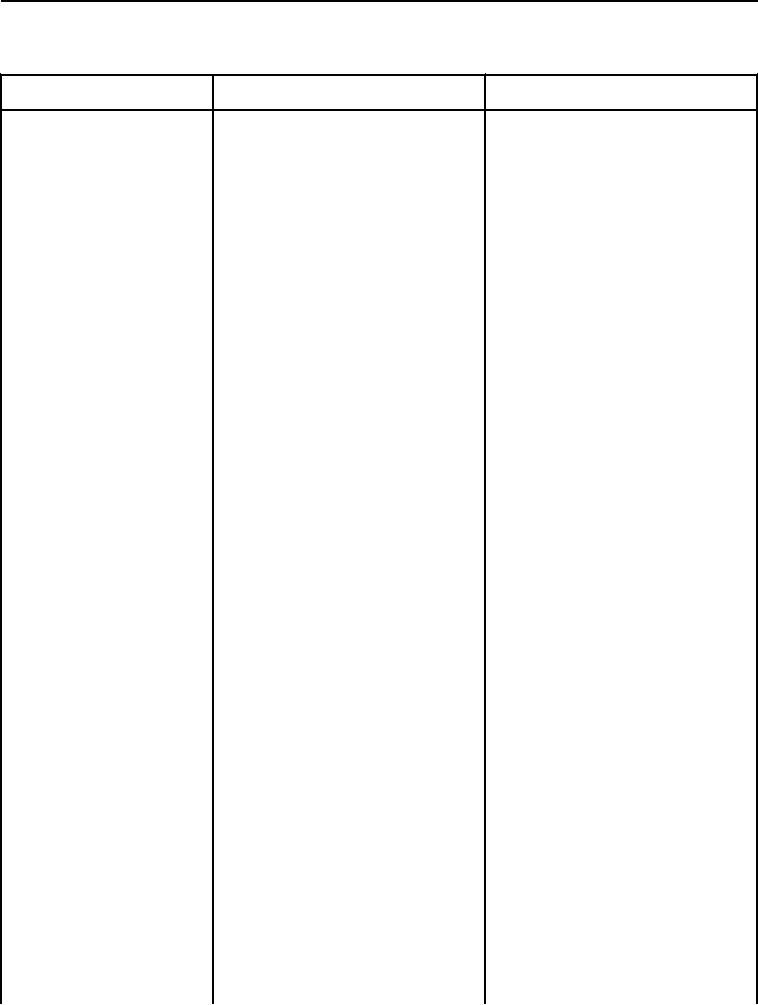

Table 1. High-Pressure Fuel Supply System Test - Continued.

Test or Inspection

Corrective Action

Malfunction

Visually inspect fuel rail

1.

If damaged or has loose pins,

26.

Fuel Rail Pressure

pressure sensor (Volume 5,

replace fuel rail pressure

Sensor Has

Damage or Loose

WP 0800, Figure 57) for

sensor. (Volume 3, WP 0429)

Pins.

damage or loose pins.

Restore machine to original

condition. Clear and refresh

DTCs. (Volume 3, WP 0362)

2.

If not damaged or does not

have loose pins, proceed to

Malfunction 27.

Measure resistance (Volume

1.

If less than 10 ohms, proceed

27.

Open Circuit

to Malfunction 28.

Between Engine

3, WP 0369) between engine

Wiring Harness

wiring harness connector J03

2.

If greater than 10 ohms,

Connector J03

socket C1 (Volume 5,

replace engine wiring

Socket C1 and

WP 0800, Figure 48) and

harness. (Volume 4,

Engine Wiring

engine wiring harness

WP 0510) Restore machine to

Harness Connector

connector P05 socket 1

original condition. Clear and

P05 Socket 1.

(Volume 5, WP 0800, Figure

refresh DTCs. (Volume 3,

57). Note reading.

WP 0362)

Measure resistance (Volume

1.

If less than 10 ohms, proceed

28.

Open Circuit

to Malfunction 29.

Between Engine

3, WP 0369) between engine

Wiring Harness

wiring harness connector J03

2.

If greater than 10 ohms,

Connector J03

socket G1 (Volume 5,

replace engine wiring

Socket G1 and

WP 0800, Figure 48) and

harness. (Volume 4,

Engine Wiring

engine wiring harness

WP 0510) Restore machine to

Harness Connector

connector P05 socket 3

original condition. Clear and

P05 Socket 3.

(Volume 5, WP 0800, Figure

refresh DTCs. (Volume 3,

57). Note reading.

WP 0362)

Measure resistance (Volume

1.

If less than 10 ohms, proceed

29.

Open Circuit

to Malfunction 30.

Between Engine

3, WP 0369) between engine

Wiring Harness

wiring harness connector J03

2.

If greater than 10 ohms,

Connector J03

socket G2 (Volume 5,

replace engine wiring

Socket G2 and

WP 0800, Figure 48) and

harness. (Volume 4,

Engine Wiring

engine wiring harness

WP 0510) Restore machine to

Harness Connector

connector P05 socket 2

original condition. Clear and

P05 Socket 2.

(Volume 5, WP 0800, Figure

refresh DTCs. (Volume 3,

57). Note reading.

WP 0362)

Measure resistance (Volume

1.

If less than 10 ohms, replace

30.

Short Circuit

engine wiring harness.

Between Engine

3, WP 0369) between engine

Wiring Harness

wiring harness connector J03

(Volume 4, WP 0510) Restore

Connector J03

socket C1 (Volume 5,

machine to original condition.

Socket C1 and

Clear and refresh DTCs.

WP 0800, Figure 48) and a

Ground.

known good ground. Note

(Volume 3, WP 0362)

reading.

If greater than 10 ohms,

2.

proceed to Malfunction 31.

0130-12