TM 5-2420-230-24-1

Table 3-6. Unit Troubleshooting Table. -- Continued

Malfunction

Test or Inspection

Corrective Action

26.

HYDRAULIC OIL OVERHEATING.

Step 1.

Check for warning light on gauge indicating return filter blockage.

If return filter is blocked, replace return filter (Para 10-10).

Step 2.

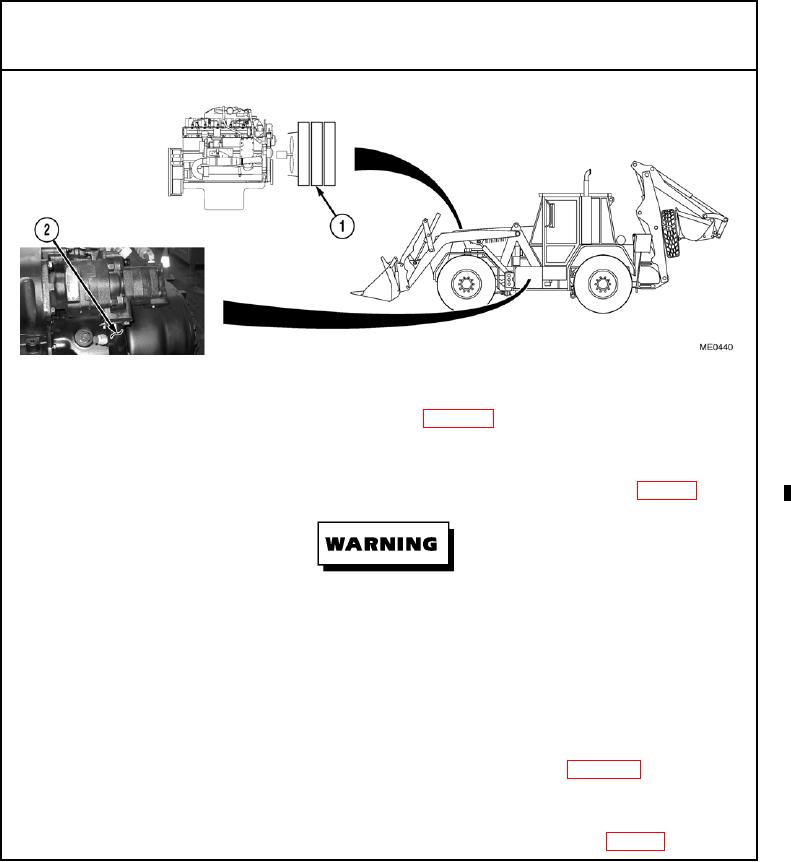

Check hydraulic oil cooler (1) for blockage or buildup.

If hydraulic oil cooler (1) is blocked or dirty, clean or replace hydraulic oil cooler (Para 9-8).

Hydraulic fluid (Dexron III) is TOXIC. Wear protective goggles and gloves; use only in

well-ventilated area; avoid contact with skin, eyes, and clothes. Skin and clothing that come in

contact with hydraulic oil should be washed immediately. Saturated clothing should be removed

immediately. Failure to comply may result in injury or death to personnel.

Do not check for leaks by hand; oil under hydraulic pressure can penetrate the skin and cause

severe injury. Failure to comply may result in injury or death to personnel.

Step 3.

Check supply line (2) for clogging, collapsing, or leaking.

If supply line (2) is clogged, collapsed, or leaking, replace supply line (Para 10-14).

Step 4.

Ensure hydraulic fan motor is operating properly.

If hydraulic fan motor is not operating properly, replace hydraulic fan motor (Para 9-6).

Change 1