TM 5-2420-230-24-1

Table 3-6. Unit Troubleshooting Table. -- Continued

Malfunction

Test or Inspection

Corrective Action

33.

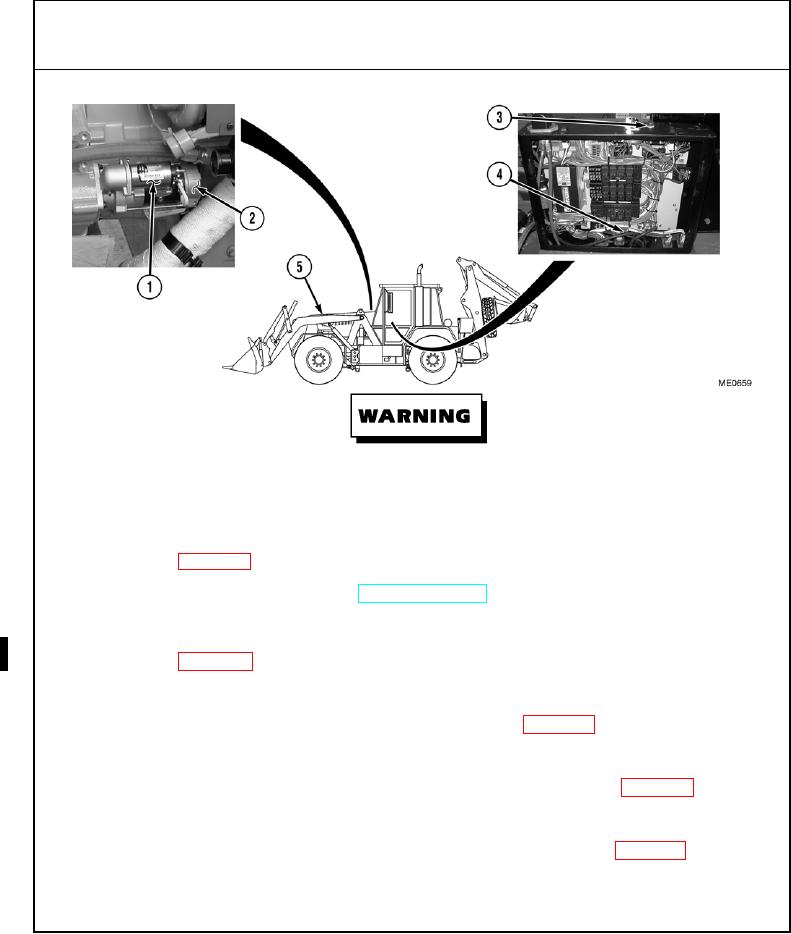

STARTER WILL NOT CRANK.

Remove all jewelry such as rings, dog tags, bracelets, etc. If jewelry or tools contact positive electrical circuits, a

direct short may result. Damage to equipment and injury or death to personnel may occur.

Step 1.

Check for 24 Vdc at terminal B on starter solenoid (1) (refer to FO-3).

If 24 Vdc is present at terminal B and starter motor (2) does not crank, replace starter motor

Step 2.

With ignition switch in IGN position (TM 5-2420-230-10), check for 24 Vdc at wire 26 on

starter button (3) (refer to FO-3).

If 24Vdc is not present at wire 26, check wire for continuity. Replace wire harness as necessary

Step 3.

Check for 24 Vdc at wire 28 on starter button (3) (refer to FO-3).

If 24 Vdc is not present at wire 28, replace starter button (Para 12-22).

Step 4.

Check starter solenoid (4) to ensure it is functioning correctly.

If starter solenoid (4) does not function correctly, replace starter solenoid (Para 12-16).

Step 5.

Check starter motor pinion to ensure it is not jammed in flywheel gear.

If starter motor pinion is jammed in flywheel gear, replace starter motor (Para 12-11).

Step 6.

Check engine (5) to ensure it is not seized.

If engine (5) is seized, notify Direct Support maintenance (Appendix L).

Change 1