TM 5-2420-230-24-1

NOTE

Ensure all hoses, wires, and tubes are disconnected and clean before removal.

Remove cable ties as necessary.

Tag all hoses, wires, and tubes, and note their positions before removal.

Cap and plug all tubes, hoses, and fittings upon removal.

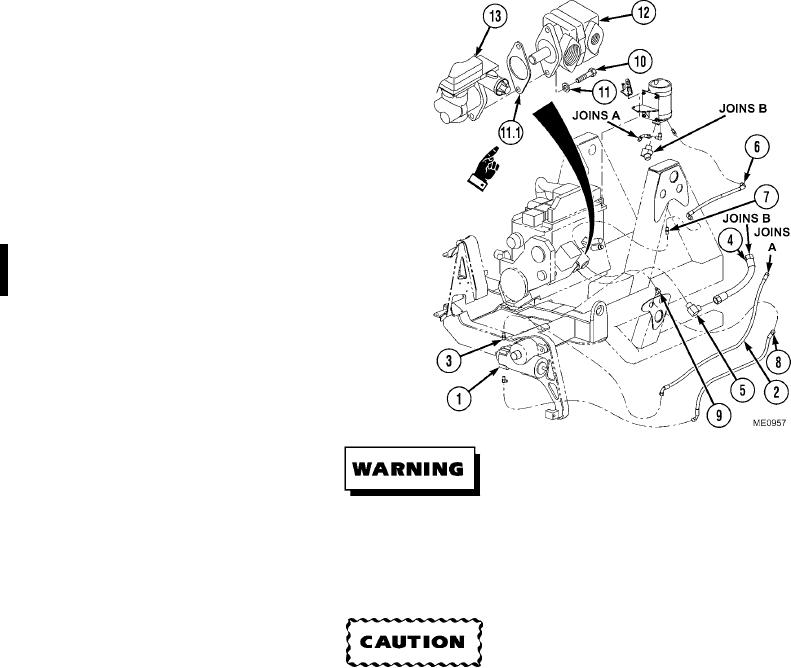

(1)

Clean power steering lines, hoses, and fluid reservoir with degreasing solvent and clean cloths.

(2)

Place drain pan under power steering box (1).

(3)

Remove hose assembly (2) from nipple (3). Allow

oil to empty into drain pan.

(4)

Remove hose assembly (4) from 90-degree

elbow (5).

(5)

Remove hose assembly (6) from nipple (7).

(6)

Remove hose assembly (8) from 90-degree

elbow (9).

(7)

Remove two bolts (10), lockwashers (11),

gasket (11.1), and power steering pump (12) from

air compressor (13). Discard lockwashers and

gasket.

(8)

Remove 90-degree elbow (5) and nipple (7) from

power steering pump (12).

b. Installation.

Adhesives, solvents, and sealing compounds burn easily and give off vapors that are harmful to the

skin and clothing. To avoid injury or death, keep away from open fire when using these materials, and

use only in well-ventilated areas. If adhesives, solvents, or sealing compounds contact the skin or

clothing, wash immediately with soap and water, and rinse thoroughly. Failure to comply may result in

injury or death to personnel.

All adaptor connections must be coated with Loctite 567 prior to installation. Do not coat hose to

adapter connections. Damage to hoses could result.

Change 1

5-14