TM 5-2420-230-24-1

Maintenance & Service Manual

R & HR32000 3 & 6 Speed LD

SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

The transmission, torque converter, an d its allied hydraulic system

5. On remote mounted torque converters remove drain plug from

are important links in the drive line between the engine and the wheels.

The proper operation of either unit depends greatly on the condition and

etc. If presence of considerable foreign material is noted, it will

operation of the other; therefore, wherever repair or overhaul of one unit

be necessary that converter be removed, disassembled and

is performed, the balance of the system must be considered before the job

cleaned thoroughly. It is realized this entails extra labor;

can be considered completed.

however, such labor is a minor cost compared to cost of

difficulties which can result from presence of such foreign

After the overhauled or repaired transmission has been installed in the

material in the system,

machine, the oil cooler, and connecting hydraulic system must be

thoroughly cleaned. This can be accomplished in several manners and a

6. Reassemble all components and use only type oil recommended in

degree of judgment must be exercised as to the method employed.

lubrication section. Fill transmission through filler opening until

fluid comes up to LOW mark on transmission dipstick. NOTE: If

The following are considered the minimum steps to be taken:

the dipstick is not accessible oil level check plugs are provided.

1. Drain entire system thoroughly.

Remove LOWER check plug, fill until oil runs from LOWER oil

hole, Replace filler and level plug.

2. Disconnect and clean all hydraulic lines. Where feasible, hydraulic

lines should be removed from machine for cleaning.

Run engine two minutes at 500-600 RPM to prime torque

converter and hydraulic lines. Recheck level of fluid in

3. Replace oil filter elements, cleaning out filter cases thoroughly,

transmission with engine running at idle (500-600 RPM).

4. The oil cooler must be thoroughly cleaned. The cooler should be

Add quantity necessary to bring fluid level to LOW mark on

"back flushed" with oil and compressed air until all foreign

dipstick or runs freely from LOWER oil level check plug hole.

material has been removed. Flushing in direction of normal oil

Install oil level plug or dipstick. Recheck with hot oil (180-200

flow will not adequately clean the cooler. If necessary, cooler

F,) [82,2-93, 3 C].

assembly should be removed from machine for cleaning, using

oil, compressed air and steam cleaner for that purpose. DO NOT

Bring oil level to FULL mark on dipstick or runs freely from

use flushing compounds for cleaning I purposes.

UPPER oil level plug.

7. Recheck all drain plugs, lines, connections, etc., for leaks and

tighten where necessary.

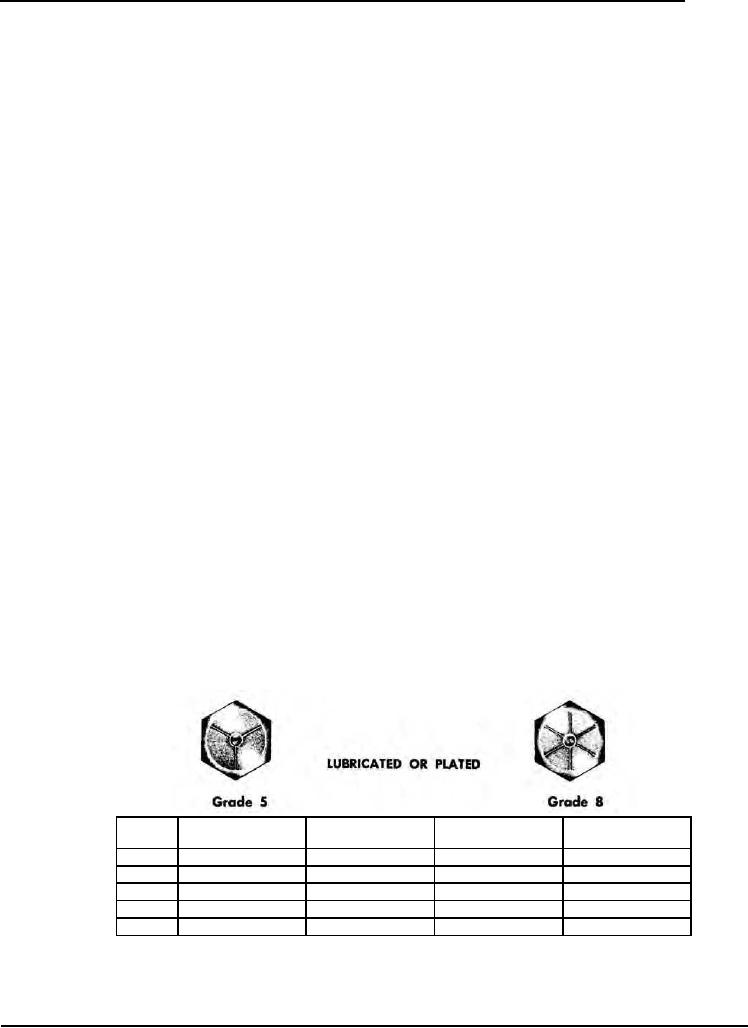

TORQUE IN (LBS.--FT.)

BOLTS, CAPSCREWS, STUDS AND NUTS

Grade 5 Identification, 3 Radial

Grade 8 Identification, 6 Radial

Dashes 120 Apart on Head of Bolt

Dashes 60 Apart on Head of Bolt

Nominal

Fine Thread

Course Thread

Fine Thread

Course Thread

Size

Torque Lbs. Ft./N.m.

Torque Lbs. Ft./N.m.

Torque Lbs. Ft./N.m.

Torque Lbs. Ft./N.m.

.3125

16-20 [21,7-27,1]

12-16 [16,3-21,7]

28-32 [38,0-43,4]

26-30 [35,3-40,7]

.3750

26-29 [35,3-39,3]

23-25 [31,2-33,9]

37-41 [50,2-55,6]

33-36 [44,7-48,8]

.4375

41-45 [55,6-61,0]

37-41 [50,2-55,6]

58-64 [78,6-86,8]

52-57 [70,5-77,3]

.5000

64-70 [86,8-94,9]

57-63 [77,3-85,4]

90-99 [122,0-134,2]

80-88 [108,5-119,3]

.5625

91-100 [123,4-135,6]

82-90 [111,2-122,0]

128-141 [173,5-191,2]

115-127 [156,0-172,2]

--56--