TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 14

SETTING " NO END FLOAT " CONDITION

14.1

Set up a dial indicator on back face of spiral bevel wheel (crownwheel) (49) as shown in fig. 10. and

screw in each diff. bearing adjusting nut (18 & 47) just sufficiently to ensure no spiral bevel wheel

(crownwheel) axial movement is registered on dial indicator.

14.2

Tap bevel casing straps (19) and rotate bevel wheel (crownwheel) then check that no axial movement is

present.

TP19

Fig No. 10

SECTION 15

SETTING THE SPIRAL BEVEL WHEEL (CROWNWHEEL) AND PINION BACKLASH

15.1

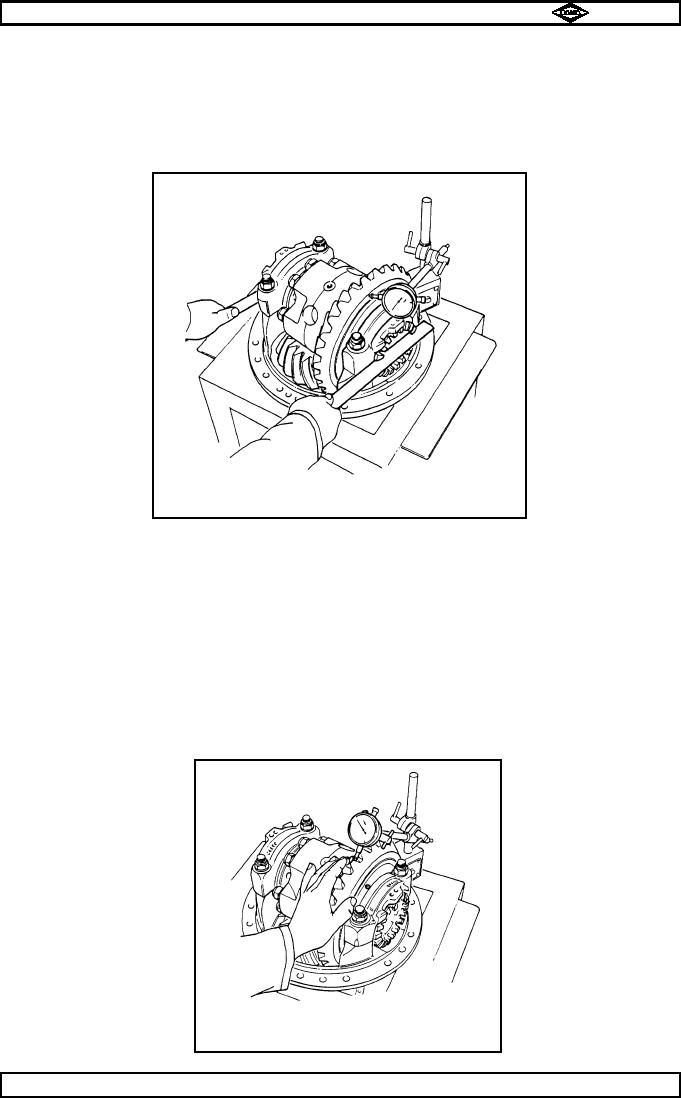

Move dial indicator onto spiral bevel wheel (crownwheel) tooth (49) as shown in fig no. 11. Hold spiral

bevel pinion (58) still and rock the spiral bevel wheel (crownwheel) (49) backwards and forwards, to

check free play between gears (backlash), and note variation of indicator reading.

Repeat above operation three more times so that four readings are taken at various positions equally

15.2

spaced around spiral bevel wheel (crownwheel) (49). The variations of readings on dial indicator must

be within limits of 0.008 " to 0.013 " (0.203 to 0.330mm) . If difference in backlash of more than half

backlash tolerance exists between any tooth mesh positions, then assembly should be further examined

for cause and rectified.

TP20

Fig No. 11

Page No.C15

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-79