TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 12

INITIAL PREPARATION BEFORE FITTING ASSEMBLED SPIRAL BEVEL WHEEL

(CROWNWHEEL) AND DIFFERENTIAL

12.1

Secure pinion and casing assembly in a suitable diff. build stool.

12.2

Check fit of diff. bearing adjusting nuts (18 & 47) as follows :-

12.3

Clean and deburr bevel casing legs (12) and bevel casing straps (19).

12.4

Fit bearing cups (17 & 46) into relevant half bores of bevel casing (12).

12.5

Check bevel casing strap studs (13), if any have been removed, replace then tighten to

88 - 98 lbs. ft. (119 - 133Nm.).

12.6

Carefully fit bevel casing straps (19) down studs (13) to locate on bearing cups (17 & 46). Check

alignment of matching marks on bevel casing legs and straps (12 & 19) to ensure that straps are not

transposed, bearing cups (17 & 46) should rest snugly in bores, and bearing adjusting nuts (18 & 47)

should be free to turn with hand pressure only, if not, it may be because of cross threading. Remove

and deburr.

Note :-

on no account should extra pressure e.g. hammer be used .

12.7

Fit diff. strap washers (20) and temporary plain nuts onto bevel casing strap studs (13) then tighten to

105 lbs ft. (142Nm.) .

12.8

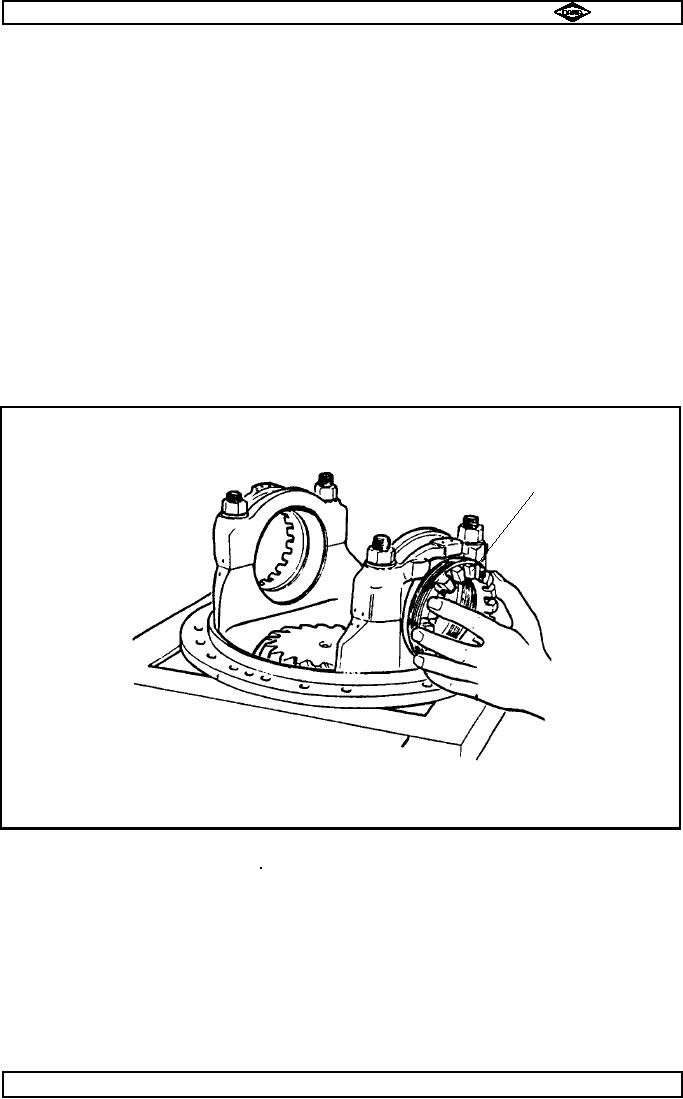

Check freedom of diff. bearing adjusting nuts (18 & 47) by unscrewing and refitting.

To assist this operation, tap bevel casing straps (19) lightly on top with a 2lb hammer. See fig. no. 7.

TP16

Diff bearing

adjusting nut (18 & 47)

●

Fig No. 7

12.9

Having checked fitting of adjusting nuts (18 & 47), remove bevel casing straps (19), bearing

cups (17 & 46) and adjusting nuts (18 & 47).

Page No.C13

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-77