TM 5-2420-230-24-1

Spicer Speciality Axle Division - Technical Publications

SECTION 8

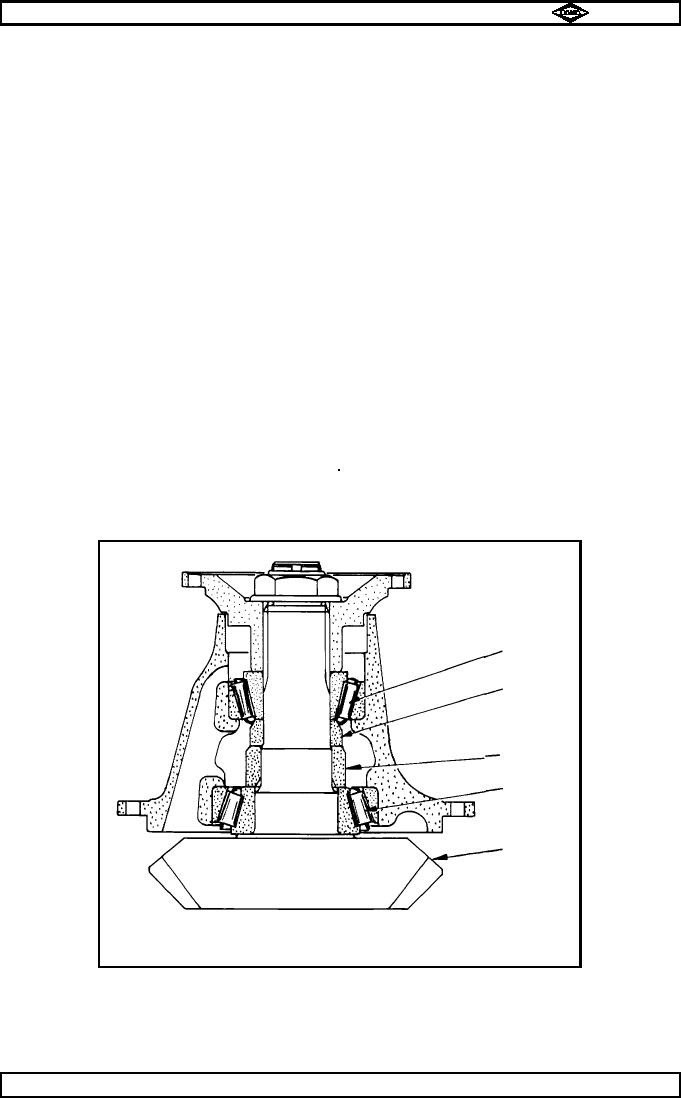

SPIRAL BEVEL PINION SUB ASSEMBLY - SEE FIG. No. 4

8.1

Fit inner and outer bearing cups (59 & 4) into their respective bores in bearing housing (7).

8.2

Press inner bearing cone (59A) onto pinion shaft (58).

8.3

Pinion assembly as follows :-

Fit inner bearing spacer (60) large inside chamfer end first, then outer spacer (61) large outside chamfer

outwards onto pinion shaft (58). Feed assembly into position in housing.

Note :-

If new parts are being fitted, then assemble with largest of available spacers.

This is to ensure that bearing pre-load is erred on low side, thus preventing too great a

pre-load and resultant bearing damage.

8.4

Press outer bearing cone (4A) into position on pinion.

8.5

Press coupling flange (2) onto pinion splines and secure with nut (1).

8.6

Place assembly in vice (clamp on holding plate fitted to coupling flange ).

8.7

Lightly oil bearings with clean gear oil ( see lubrication instructions at front of manual for specification),

then progressively tighten nut (1) whilst rotating and shock loading bearing housing (7) with a rawhide

mallet, to torque setting of 800 - 900 lbs. ft. (1085 - 1220 Nm).

8.8

Remove assembly from vice, take off holding plate.

TP72

Outer bearing

Outer spacer

Inner spacer

Inner bearing

Pinion

Fig No. 4

Page No.C9

Manual No. 1785 Issue A

Spicer Speciality Axle Division

J-73